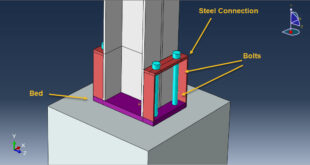

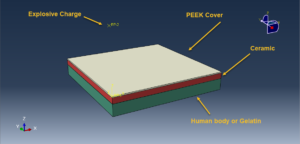

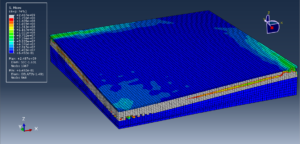

In this tutorial, the َAir blast simulation of PEEK/ceramic/gelatin composite for finding behind the armor trauma in Abaqus has been investigated. The polyether-ether-ketone(PEEK) is modeled as a thin solid layer to protect the other layers. The silicon carbide or ceramic is modeled as a three-dimensional solid layer at the middle. The gelatin or human tissue is model as a three-dimensional solid layer as a back plate. You can see a figure of the assembled parts below

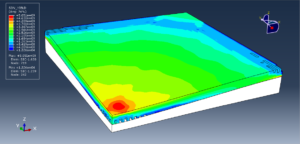

A ceramic-based armor system must arrest bullet penetration and dissipate a large amount of impact energy. Taking the total linear momentum transferred to the wearer of a ceramic armor as a measure of the behind-armor ballistic/blunt trauma (BABT), we study the effect on the BABT of adding a thin polyether-ether-ketone (PEEK) layer on the face of a Silicon Carbide (SiC) ceramic target under blast load to investigate the effect of detonation over the human tissue

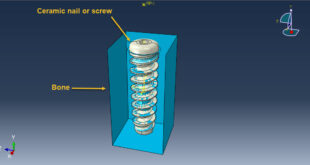

The SiC is modeled as a Johnson-Holmquist (JH-2) material model. The SiC material is very hard and mainly used under compressive load conditions and can only sustain very little tension. Typical applications include bulletproof vests and car brakes due to its high endurance. The strength has a dependence on pressure. In high-speed impact applications, damage to the material plays an important role in the evolution of the strength. The totally failed silicon carbide will not sustain any load. The JH-2 model assumes that the damage variable increases progressively with plastic deformation

To model PEEK, the Johnson-Cook hardening and damage is selected. To model gelatin elastic-plastic material format is acceptable. All materials are assumed to be homogeneous and isotropic. In order to quantify the momentum transferred to the wearer of the ceramic armor, the PEEK layer is bonded to the ceramic

The dynamic explicit step is is so appropriate for this type of analysis. The perfect contact is assumed between the panel layers, also cohesive contact can be used. The CONWEP air blast procedure is selected to demonstrate the blast pressure on the panel surface. The symmetric boundary conditions are assigned to the two symmetry surfaces or sides of the panel. The mesh should be fine to obtain the correct results

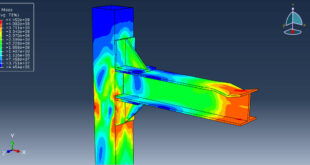

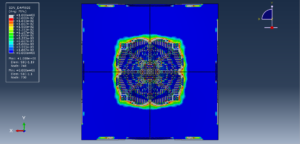

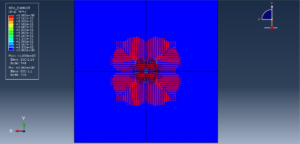

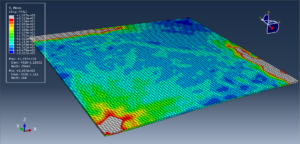

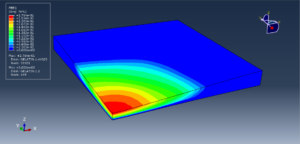

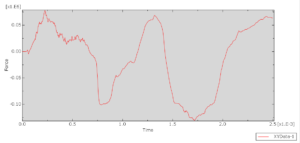

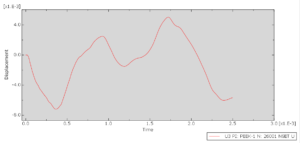

After the simulation all results such as stress, strain, damage, failure, fracture, force-displacement diagram,… are available, you can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-six Euros. you can click on the bellow bottom to begin the process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس