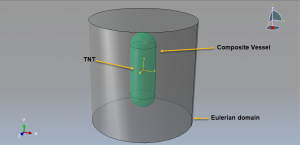

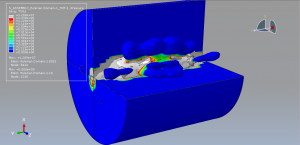

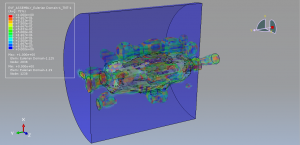

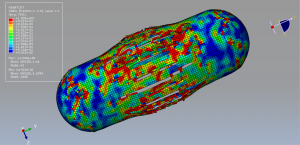

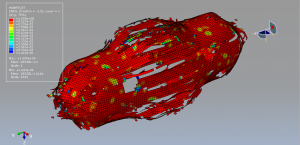

In this tutorial the Simulation CEL explosion inside the CFRP composite vessel in Abaqus has been investigated. The CFRP vessel is modeled as a three-dimensional shell part in sixteen layers with different oreintation. The TNT part is modeled as a three-dimensional solid part. The surounding is modeled as an Eurlerian part. You can see a figure of the assembled parts below

.Composite pressure vessels have been used extensively for storing compressed natural gas on vehicles and similar storage concepts are being developed for hydrogen gas storage. In the context of hydrogen gas pressure systems, composites are fiber-reinforced polymer-matrix materials, commonly referred to as fiber-reinforced polymers (FRP). Carbon fibers are the structural fiber of choice, although they are currently prohibitively expensive for high-volume applications. In this example CFRP is selected for the material. Damage initiation refers to the onset of degradation at a material point. In Abaqus the damage initiation criteria for fiber-reinforced composites are based on Hashin’s theory. These criteria consider four different damage initiation mechanisms: fiber tension, fiber compression, matrix tension, and matrix compression. The elastic lamina type with Hashin damage model is used for the vessel.

.Composite pressure vessels have been used extensively for storing compressed natural gas on vehicles and similar storage concepts are being developed for hydrogen gas storage. In the context of hydrogen gas pressure systems, composites are fiber-reinforced polymer-matrix materials, commonly referred to as fiber-reinforced polymers (FRP). Carbon fibers are the structural fiber of choice, although they are currently prohibitively expensive for high-volume applications. In this example CFRP is selected for the material. Damage initiation refers to the onset of degradation at a material point. In Abaqus the damage initiation criteria for fiber-reinforced composites are based on Hashin’s theory. These criteria consider four different damage initiation mechanisms: fiber tension, fiber compression, matrix tension, and matrix compression. The elastic lamina type with Hashin damage model is used for the vessel.

The Jones-Wilkins-Lee (or JWL) equation of state models the pressure generated by the release of chemical energy in an explosive. This model is implemented in a form referred to as a programmed burn, which means that the reaction and initiation of the explosive is not determined by shock in the material. Instead, the initiation time is determined by a geometric construction using the detonation wave speed and the distance of the material point from the detonation points. To model TNT behavior, JWL material model is selected.

Abaqus dynamic explicit step is appropraite for this type of analysis. The general contact capability with conctact property is defiend for all domains. The volume fraction methos is used to define TNT amount and its location inside the Eulerian domain. The mesh for all part should be fine to get the proper results.

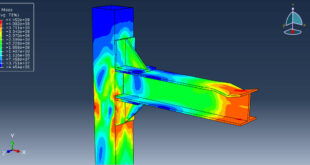

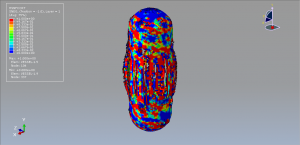

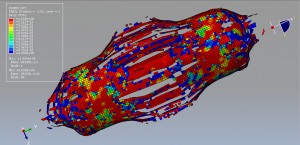

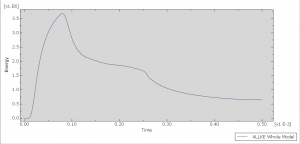

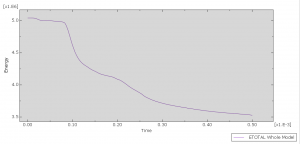

You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس