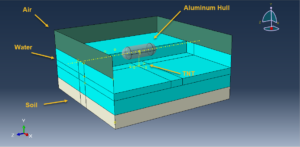

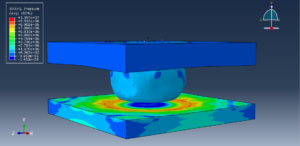

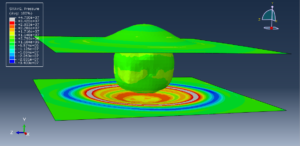

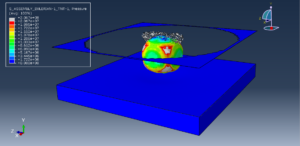

In this tutorial, the Simulation under-water explosion by using the CEL method near a floating structure in Abaqus has been investigated. The aluminum hull is modeled as a three-dimensional thick shell part. The Soil, TNT, Water, and Air are modeled as three-dimensional parts inside the Eulerian domain. You can see a figure of the assembled parts below

Underwater explosion involves many difficult problems, such as problems of fluid–solid coupling and additional water mass and liquid jets. In most cases, damage done to structures occurs early on and is due to the striking of the shock wave. All ships are liable to collisions and in wartime they are liable to enemy attack. The most serious threats to a ship’s survival are probably collision or an underwater explosion. Collisions are dealt with under damage stability. The detonation of an explosive device leads to the creation of a pulsating bubble of gas containing about half the energy of the explosion. The field of underwater explosions and shock physics is both complex and fascinating. Many aspects of the underwater explosion event must be studied properly to understand the development and propagation of the dynamic shock loading through the fluid.

To model TNT or explosive material, the JWL equation of state is selected. The JWL equation of state (EOS) is frequently used for the products (and sometimes reactants) of a high explosive (HE). Here we review and systematically derive important properties. The JWL EOS is of the Mie-Grueneisen form with a constant Grueneisen coefficient and a constant specific heat.

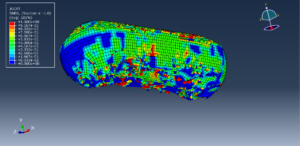

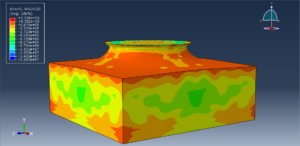

To model soil behavior, the More-Coulomb plasticity with elastic data is selected. To model water, the Us-Up linear shock model is considered. The Air is modeled as an ideal gas format. To model aluminum behavior under severe load, the Johnson-Cook hardening and damage are selected

The dynamic explicit step with a general contact capability is used in this tutorial, the general contact algorithm is so suitable here because of the complex contact situation. The proper mechanical and Eulerain boundaries are assigned to the parts. The uniform material method to define the mass and volume of the TNT and other parts is considered. The mesh should be fine to obtain the correct results

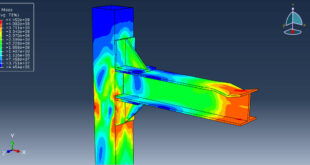

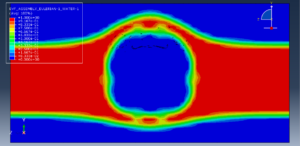

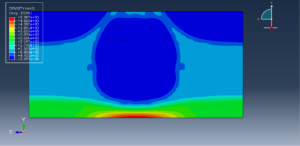

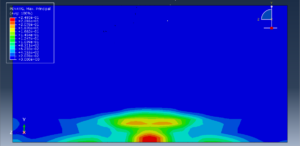

After the simulation stress, strain, explosion wave, damage, soil deformation, and other results are available. You can see some figures of the results below

You can provide CAE, INP, and English video files of this simulation here. The cost of these files is Thirty-Six Euros. you can click on the bellow bottom to begin the process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment, send me an email to this address: karampourp@gmail.com

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس