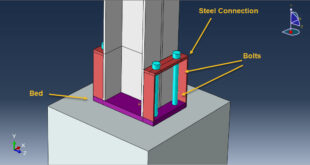

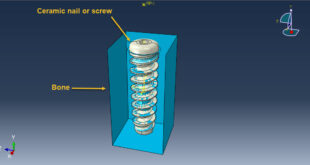

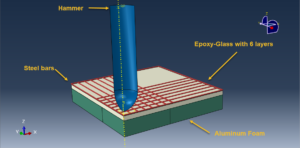

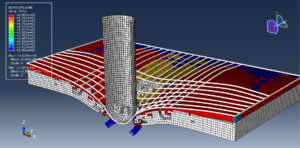

In this tutorial, the Numerical Investigation of Rigid Impact on Steel Wire Reinforced Foam Core/Composite Skin Sandwich Panel in Abaqus software has been investigated. The rigid projectile is modeled as the three-dimensional shell part. The steel reinforcements are modeled as wire part. The glass-epoxy part is modeled as a three-dimensional shell part with six layers. The metal foam is modeled as a three-dimensional solid part. you can see a figure of the assembled parts below

Due to the high physical-mechanical properties in terms of high strength and stiffness to weight ratios, high corrosion resistance and the low thermal and acoustics conductivity, glass fiber reinforced sandwich composite structures are increasingly used as load-carrying components in many engineering areas including aerospace structures, automobile, biomedical, marine applications, and transportation.The study of low and high energy impact damage is one of the most debated subjects in the industrial application and it should be considered in the design phased especially in the sandwich structures

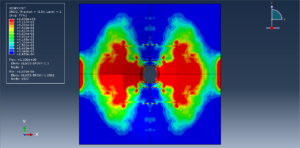

Numerous criteria have been presented on the degradation of composites laminates so far, which stems from the difference in the material properties and manufacturing methods. However, some of these criteria are commonly used and have shown good accuracy in studying the behavior of composite laminates. Also, in this study, Hashin’s theory is used.According to this theory, three-dimensional failure criteria of unidirectional fiber composites is determined, which is expressed as quadratic stress polynomials. This criterion consists of four damage initiation modes, which are: fiber tension, fiber compression, matrix tension, and matrix compression. The elastic material model with Hashin’s damage criterion is selected for the galss-epoxy part

For the steel reinforcement, the elastic-plastic model with damage criterion is considered. The JC model is so approapriate for the steel material under high strain rate load

The metal foam material is defined as the elastic property with Crushable foam damage to consider the compression and damage

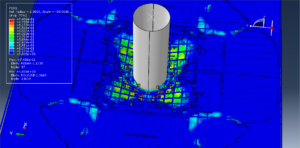

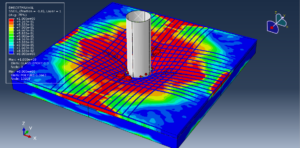

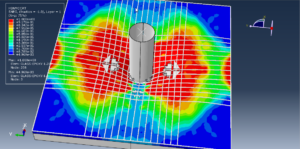

An ABAQUS Dynamic/Explicit package is used for the finite element modeling of the low nad high-velocity impact. Explicit method can converge the dynamic equation, also consider element failure. The general contact algorithm with contact property is selected for this analysis. The proper boundary conditions are assigned to the pane and initial velocity to the rigid body. The mesh should be fine to obtain the correct results

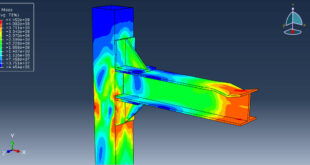

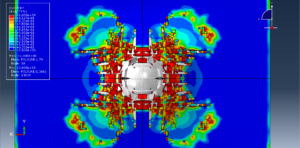

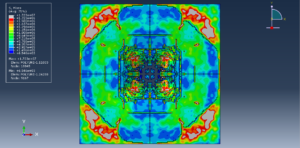

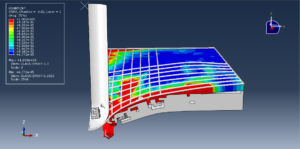

After the simulatio, all results such as stress, strain, damage, failure, and … are available. you can see some figure for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-eight Euros. you can click on the bellow bottom to begin the process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس