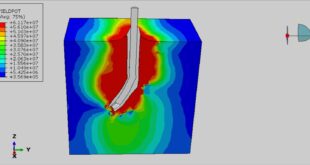

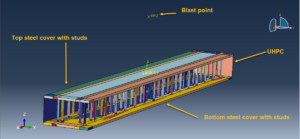

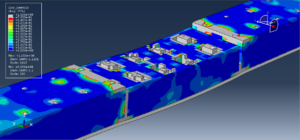

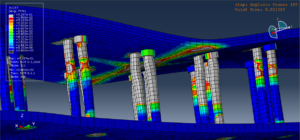

In this tutorial, the Simulation air blast explosion over a steel-UHPC-steel sandwich composite beam stud connectors in Abaqus has been studied. The two steel plates with studs are modeled as three-dimensional solid part. The UHPC is modeled as a three-dimensional solid part as a core of the sandwich beam. You can see a figure of the assembled parts below

Sandwich structures can be defined as a subset of multilayered composite structures, optimized for the anticipated lifetime loading conditions. A typical sandwich structure consists of the outer facings and the core embedded between them.High-rise buildings have experienced rapid developments since the middle of the 20th century. As height increases, lateral loads like the wind and seismic effects, instead of gravity loads, become the dominant factor in structural analysis.The growing demand for large-size structures and high-rise buildings, especially in high-seismic risk areas, increased the need to find structural elements with high strength-to-weight ratios. This can be achieved by improving the material properties and/or by introducing new technologies or structural systems. One such technique is to sandwich a concrete core between two parallel but connected steel plates. This sandwich system is called a “steel–concrete–steel (SCS)” structural system. SCS is a special form of composite systems that originated in civil engineering applications and was extended to many other applications including marine structures and nuclear power plants

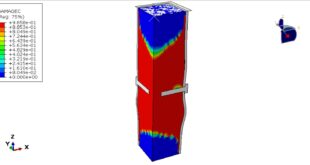

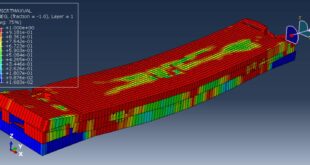

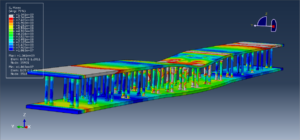

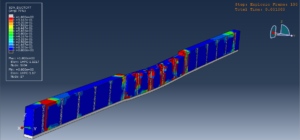

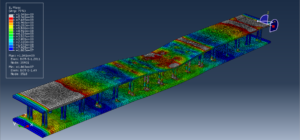

The Johnson-Cook hardening and damage criterion for the steel members is selected. Because of the rapid deformation, which happens during the blast analysis, the JC model would be appropriate for this type of analysis. To model ultra-high-performance-concrete behavior under severe load, Johnson-Holmquist model can be used to demonstrate the damage and failure when the beam receives the blast load. The dynamic explicit step with a mass scale to make analysis faster is considered. Two surfaces of the steel plates are tied to the concrete beam, and the studs are embedded inside the concrete host. The CONWEP blast procedure by using the amount of TNT and its location is selected. The proper boundary condition is assigned to the two ends of the sandwich beam. The mesh should be fine to obtain the correct results

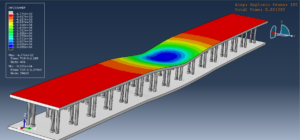

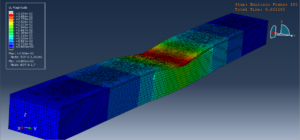

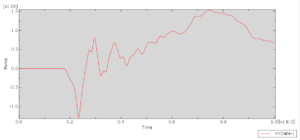

After the simulation, all resutls such as stress, strain, damage, failure, and … are available. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-six Euros. you can click on the bellow bottom to begin the process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials