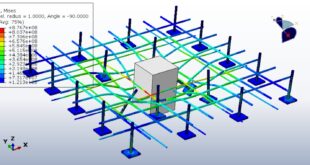

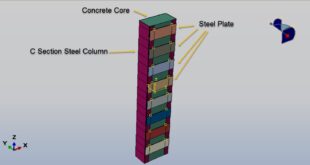

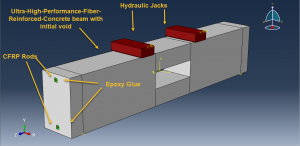

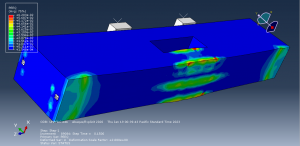

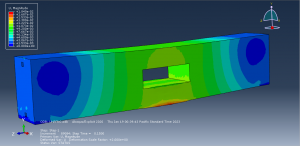

In this tutorial, the Simulation UHPFRC beam with initial void reinforced with CFRP rod and Expoxy under dynamic bending has been investigated. The concrete beam, CFRP rod, epoxy glu are modeled as three-dimensional solid parts. Two rigid body as a hydraulic jacks also are modeled. You can see a figure of the assembeld parts below

Ultra High Performance Concrete (UHPC) is a cementitious composite characterized by a significant amount of cement, small aggregates size, binder, and a low water/cement ratio. This mix design creates a dense and interconnected microstructure with high homogeneity, a capillary porosity lower than two present, and and a compressive strength higher than one haundred fifty MPa. These characteristics result in a concrete with better performance, higher durability and increased bearing capacity and toughness compared to normal and high strength concretes. The incorporation of fibers significantly improves the tensile capacity, leading to a high deformability with a pseudo-plastic phase (multi-cracking) and an increase in the tensile capacity before crack localization and strength depletion. As a result, the UHPFRC can be classified as a new cementitious material. Its mechanical behavior should be adequately characterized to fully take advantage of its unique properties in structural design, making possible the construction of lighter, more durable, efficient and innovative structural elements

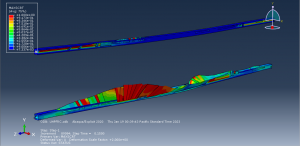

To model UHPFRC bea, the Concrete Damaged Plasticity model is selected. The model is a continuum, plasticity-based, damage model for concrete. It assumes that the main two failure mechanisms are tensile cracking and compressive crushing of the concrete material. To model CFRP, elastic data as engineering constans is considered. The traction with damage model is selected for the glue epoxy as a cohesive material. The dynamic explicit step with a specific time and a mass scale to reduce the inertia effect is used. The perfect contact is considered between concrete and epoxy, epoxy and CFRP rod. The surface to surface contact algorithm with contact property is selected for the contact between rigid body parts and concrete. The fixed boundary condition is assigned to two ends of the beam, and displacement as load to two rigid body parts. The mesh should be find to obtain proper results

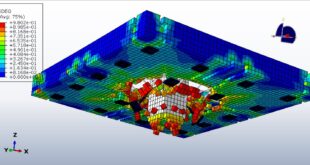

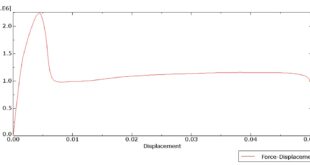

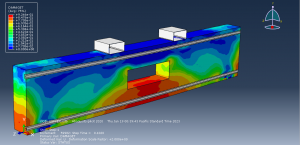

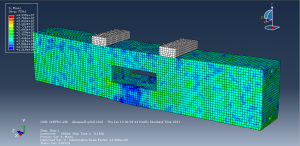

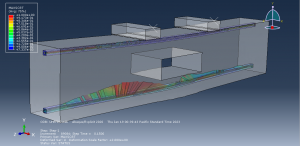

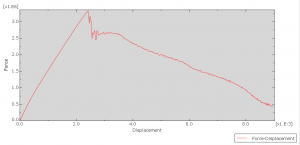

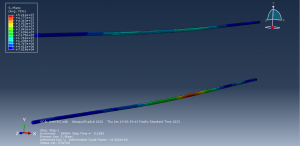

After the simulation all results such as stress, strain, damage in epoxy and concrete, force-displacement diagram, … are available. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials