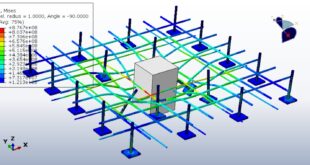

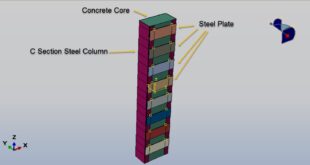

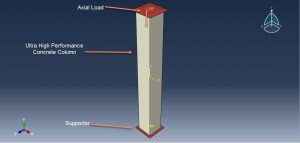

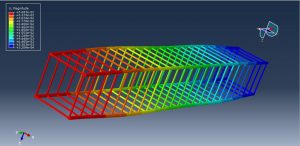

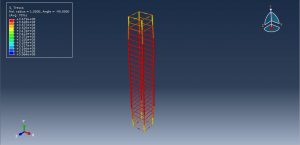

In this tutorial, the Simulation axial compression of the Ultra-High-Performance Concrete column in Abaqus has been investigated. Ultra-High Performance Concrete (UHPC) is an advanced technology in the concrete industry with superior characteristics such as high strength in compression and tension, ductility, and durability. The concrete column is modeled as a three-dimensional solid part and the embedded bars in the column are modeled as three-dimensional wire parts. Two rigid shell bodies are used as supporter and force body. You can see a figure of the assemble parts at below

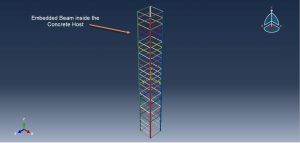

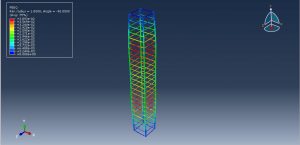

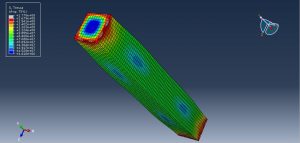

To model bars or beams material, steel with elastic-plastic material is used. The simulation of UHPC material through commercial FE software allows for the study of the structures including UHPC.the concrete plasticity dam-age (CDP) model in the Abaqus software can predict the behavior of the concrete with reasonable accuracy. This model has been employed by researchers to model conventional concrete. The concrete material parameters used in this study are the modulus of elasticity (E), Poisson’s ratio (v), and the CDP parameters. In the CDP, for cracked concrete, a constant value for Poisson’s ratio is considered. The primary values of the CDP parameters include dilation angle (w), shape factor (Kc), stress ratio rb0/ rc0, eccentricity, and viscosity parameter. The general static step with some changes in the convergence model is used. The general contact algorithm with contact property is implied. The bemas are embedded inside the concrete column host. The fixed boundary conditions are assigned to the bottom rigid body and the displacement boundary is assigned to the top rigid body to apply compression load on the UHPC column. The mesh should be fine to obtain good results.

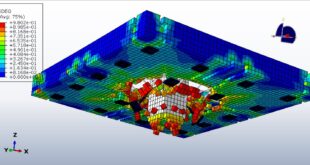

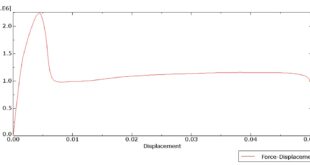

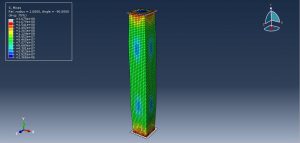

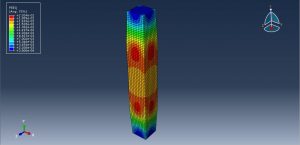

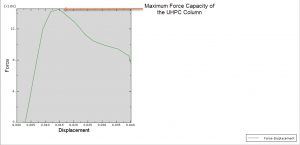

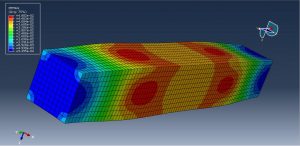

After the simulation all results such as stress, strain, displacement, and the froce-displacement diagram are achievable. Base on the force-displacement diagram, the failure zone can be specified. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials