Introduction to Simulation of Blast Resistance Behavior of Adhesively Bonded Cross-Laminated Timber-Concrete Composite (CLT-CC)

Overview

The simulation of blast resistance behavior in adhesively bonded cross-laminated timber-concrete composites (CLT-CC) represents an emerging area of research in structural engineering and blast mitigation. This composite system combines the advantages of cross-laminated timber (CLT) and concrete to create hybrid structures with improved performance under extreme loading conditions

Composite System Characteristics

CLT-CC systems typically consist of

Cross-laminated timber panels (3-7 layers of orthogonally arranged wood boards)

Concrete topping layer (usually 50-150mm thick)

High-performance adhesive interface bonding the two materials

Blast Resistance Considerations

The blast resistance of CLT-CC composites depends on

Material properties: Timber’s energy absorption capacity and concrete’s compressive strength

Composite action: Effective stress transfer through the adhesive layer

Failure modes: Delamination, timber fracture, and concrete crushing

Dynamic response: Strain rate effects on material behavior

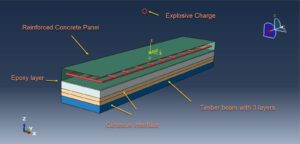

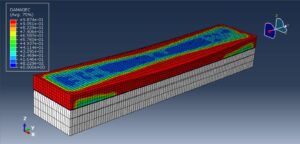

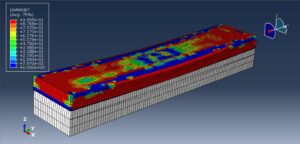

You can see a figure of the assembled part in Abaqus below

Key Simulation Challenges

Accurate modeling of rate-dependent material properties

Representation of complex adhesive interface behavior under dynamic loading

Computational efficiency for large-scale simulations

Applications

Understanding blast resistance through simulation enables

Design of more resilient hybrid structures

Retrofit solutions for existing buildings

Development of performance-based design guidelines

Optimization of material combinations and thicknesses

In this example, the epoxy is used as the interface between the concrete and the first wood layer, and cohesive interaction is used between the wood layers. The CONWEP air blast model is selected. CONWEP (Conventional Weapons Effects Program) is an empirical blast load model developed by the U.S. Army and implemented in ABAQUS (via the Explosive Load or Blast Load option) to simulate airblast effects from high explosives. It is based on experimental data and provides a simplified yet efficient way to model blast pressure waves without explicitly modeling the explosive detonation or fluid-structure interaction (FSI)

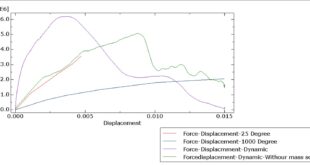

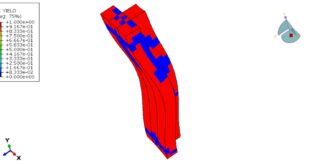

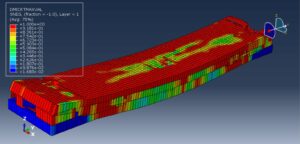

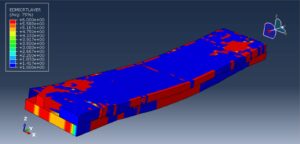

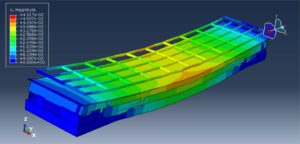

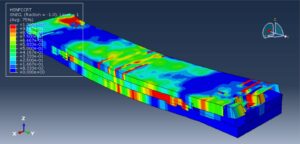

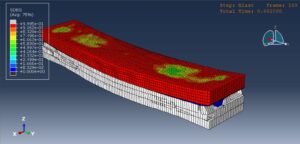

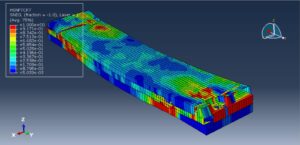

After the simulation, all results such as stress, strain, failure, damage, wood failure, compression and tension damage, cohesive interaction failure, and others are available. You can see some figures of the results below

You can provide this simulation’s CAE, INP, and English video files here. The price of these files is Twenty-Six Euros. You can click on the button below to begin the process

Our Payment methods are: Tether, Bitcoin, TRX, PayPal, Visa, or Mastercard. Just before payment, send us an email to this address: abaqusfem.com@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials