Introduction to Numerical Study on CFRP-Lined Concrete Cylinder Pipe (CCP) Under Internal Explosion

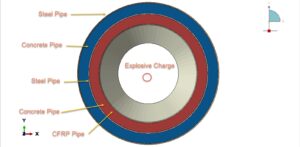

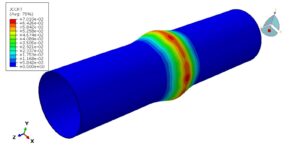

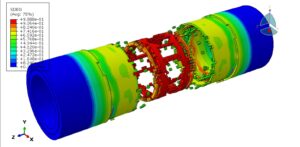

Concrete Cylinder Pipes (CCPs) are widely used in water transmission systems due to their high load-bearing capacity and durability. However, they are vulnerable to internal explosions caused by accidental gas ignition or deliberate attacks, leading to catastrophic failures. To enhance blast resistance, Carbon Fiber-Reinforced Polymer (CFRP) liners have been proposed as a strengthening solution due to their high strength-to-weight ratio and corrosion resistance. In this tutorial, five layers are used. You can see a figure of the assembled parts below

A numerical study on CFRP-lined CCP under internal explosion involves advanced computational modeling to simulate dynamic responses, damage mechanisms, and failure modes. Key aspects include

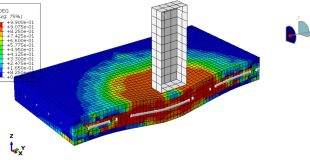

Finite Element Modeling (FEM) – High-fidelity 3D models are developed using software like LS-DYNA, ABAQUS, or ANSYS, incorporating material nonlinearities, prestressing effects, and blast loading

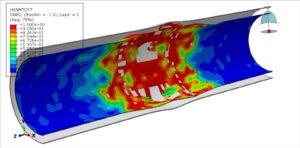

Blast Load Simulation – Explosive pressures are modeled using empirical equations (e.g., CONWEP) or coupled Eulerian-Lagrangian (CEL) techniques to simulate shockwave propagation

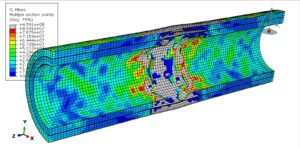

Material Behavior

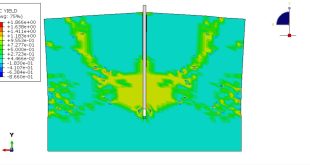

Concrete: Damage plasticity models (e.g., CDP in ABAQUS) capture cracking and crushing

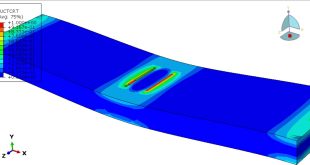

CFRP: Orthotropic elastic properties with progressive damage criteria for fiber/matrix failure

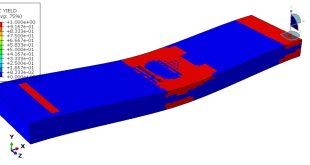

Prestressing wires: Elasto-plastic behavior with bond-slip effects

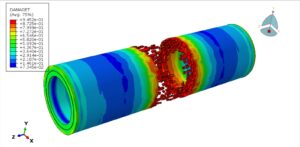

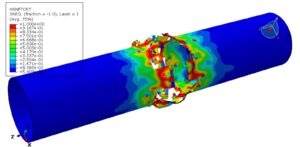

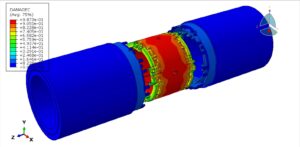

Failure Modes – The study evaluates

Concrete spalling and radial cracking

CFRP delamination or rupture

Wire breakage and loss of prestress

Parametric Analysis – Investigates the influence of CFRP thickness, layup configuration, and explosive charge magnitude on structural resilience

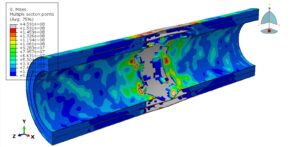

In this example, the dynamic explicit step and CONWEP method, as the explosion procedure, are selected. After the simulation, all results such as stress, strain, damage, failure, and others are available. As a comparison, two materials for concrete are considered, first normal concrete, and the second, Ultra-High-Performance Concrete

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials