Introduction to Blast Resistance Behavior of Interior Voided Slab-Column Connections Using Steel Sheets and CFRP Reinforcement

Background and Significance

Modern structures, particularly those in high-risk environments, require enhanced resistance to extreme loading conditions such as blast loads. Slab-column connections are critical zones in reinforced concrete (RC) frames, often susceptible to punching shear failure under sudden dynamic loads. Voided slabs, which reduce self-weight while maintaining structural efficiency, introduce additional challenges in blast resistance due to their reduced cross-sectional area

To mitigate these vulnerabilities, advanced strengthening techniques such as steel sheets and Carbon Fiber Reinforced Polymer (CFRP) reinforcement have been explored. Steel sheets provide ductility and energy absorption, while CFRP offers a high strength-to-weight ratio and corrosion resistance. Understanding their combined effect on the blast resistance of voided slab-column connections is essential for optimizing structural safety

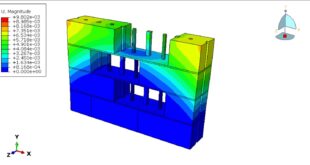

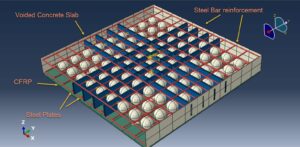

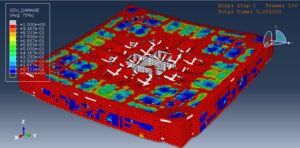

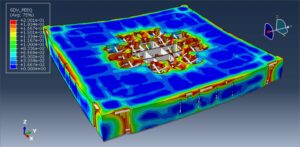

You can see a figure below of the assembled parts in Abaqus

Challenges in Voided Slab-Column Connections Under Blast Loading

Punching Shear Vulnerability: Reduced concrete area around voids increases the risk of shear failure

Dynamic Load Effects: Blast-induced high strain rates alter material behavior, requiring ductile reinforcement

Progressive Collapse Risk: Failure at connections can lead to catastrophic structural collapse

Role of Steel Sheets and CFRP Reinforcement

Steel Sheets: Enhance energy dissipation through plastic deformation, improving ductility

CFRP Reinforcement: Increases flexural and shear capacity while preventing brittle failure

Hybrid Strengthening: Combining both materials can optimize blast resistance by balancing strength and ductility

Research Objectives

This study investigates

The blast resistance behavior of voided slab-column connections

The effectiveness of steel sheets and CFRP in mitigating punching shear failure

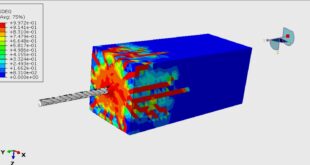

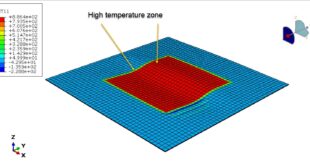

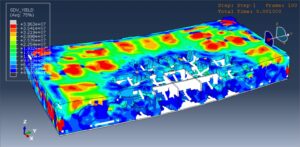

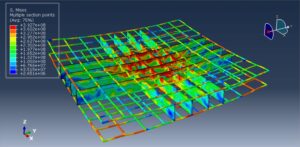

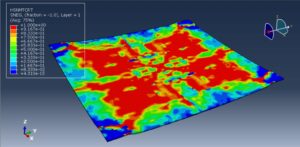

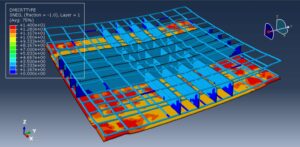

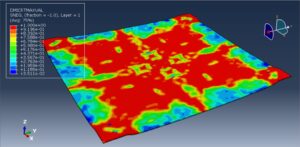

After the simulation, all results such as stress, strain, damage, failure, deformation, CFRP damage, and others are available. You can see some figures for the results below

You can provide this simulation’s CAE, INP, and English video files here. The price of these files is Twenty-Six Euros. You can click on the button below to begin the process

Our Payment methods are: Tether, Bitcoin, TRX, PayPal, Visa, or Mastercard. Just before payment, send us an email to this address: abaqusfem.com@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials