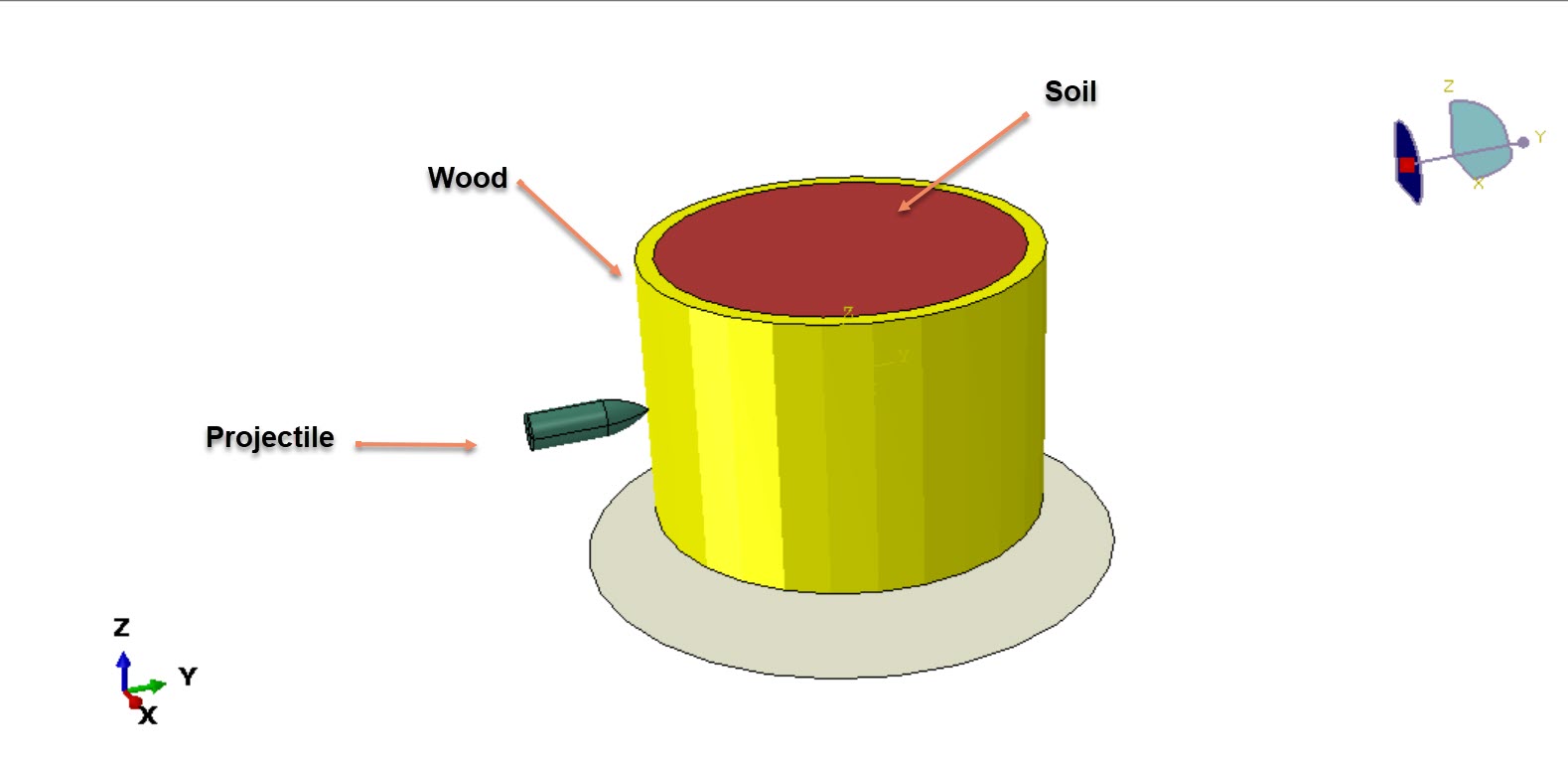

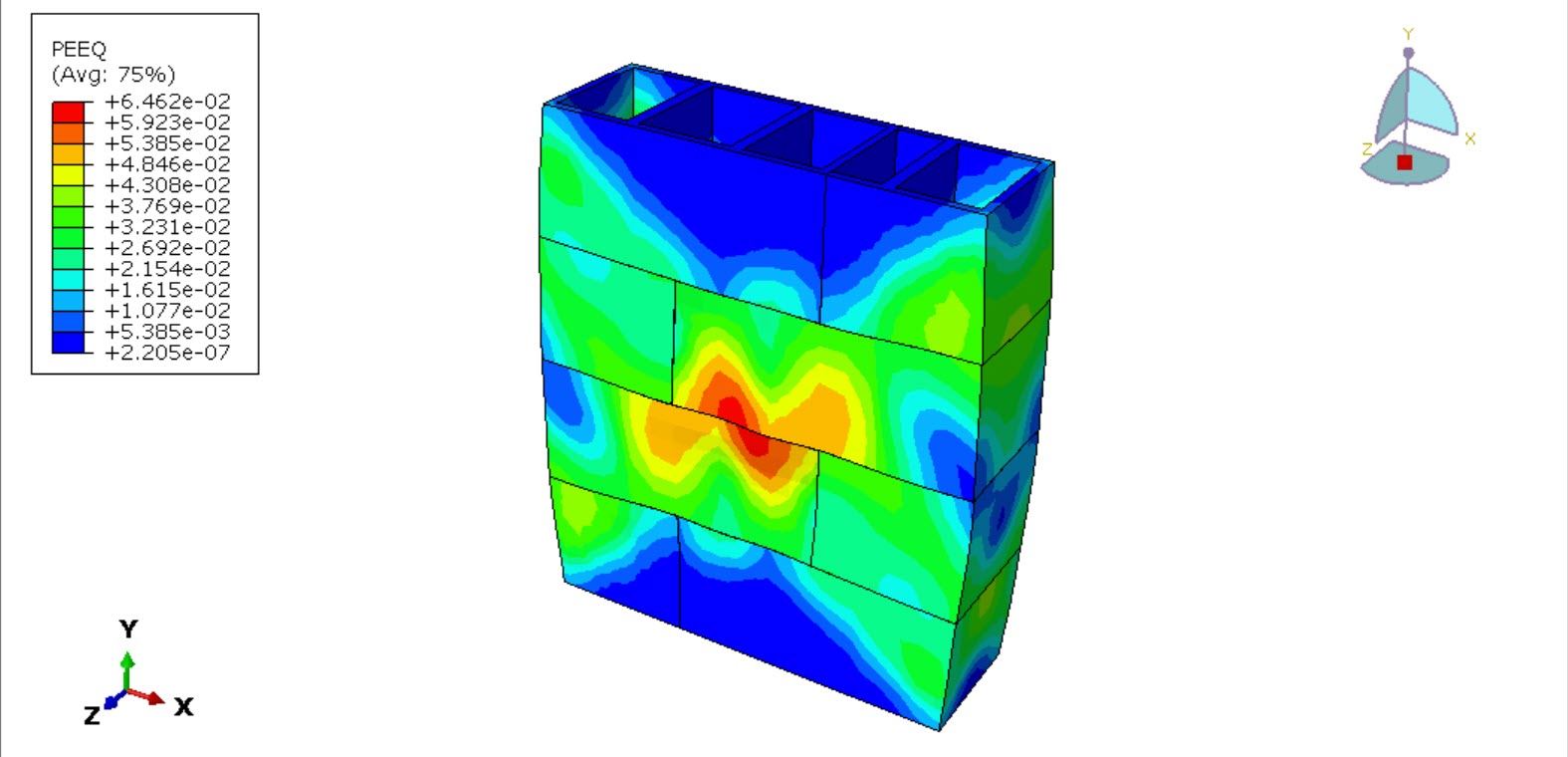

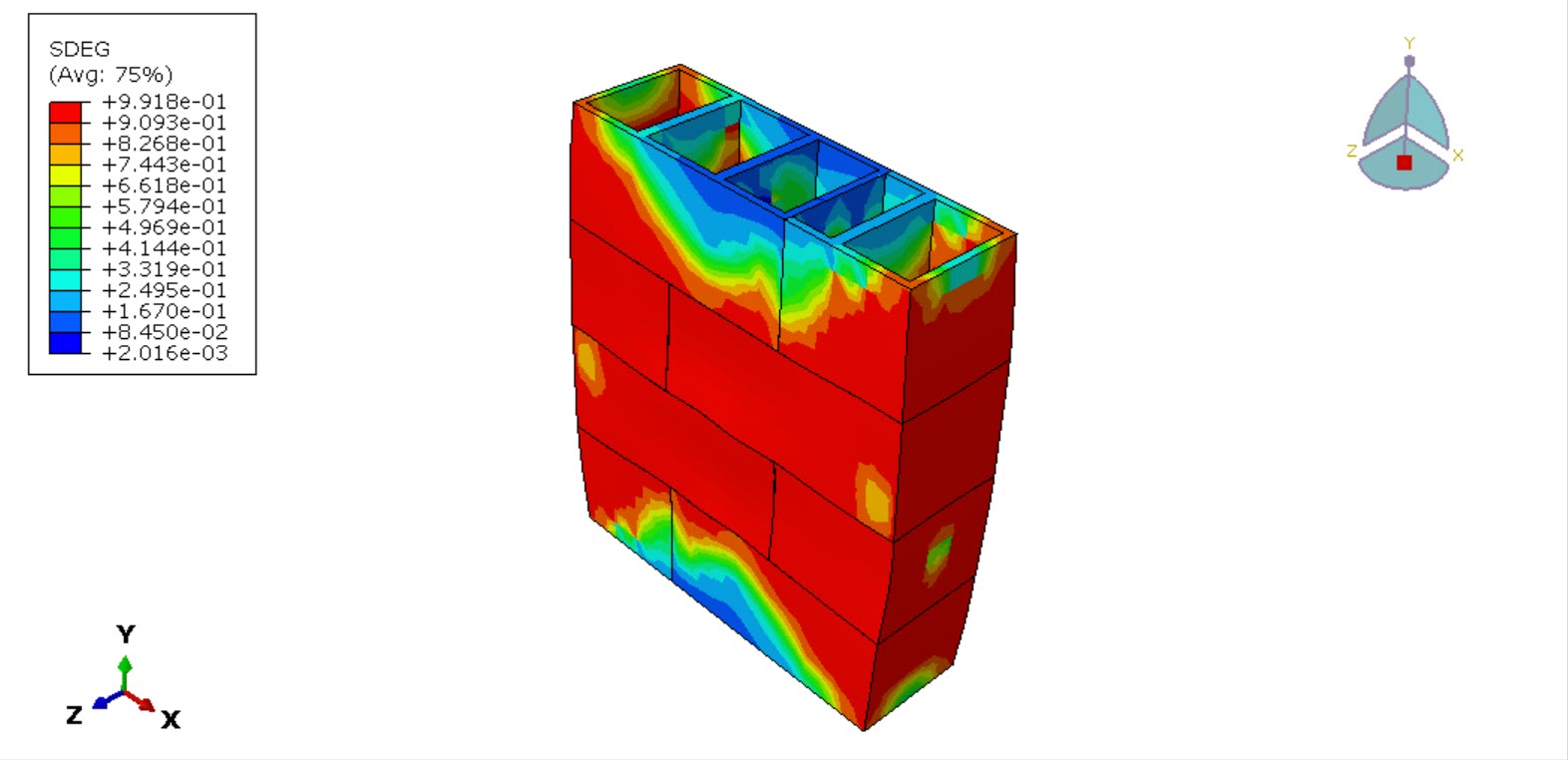

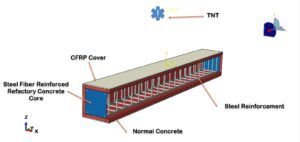

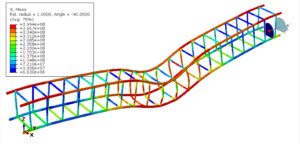

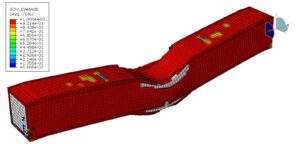

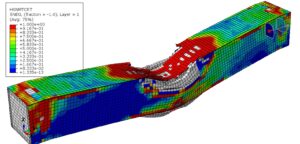

In this example, an SSFRRC beam with a normal concrete outer layer, CFRP composite material, and steel bars as reinforcement is considered. To model the SSFRRC beam, the Concrete Damaged Plasticity model is used for the refractory concrete; the Johnson–Holmquist model is applied to the normal concrete; the Johnson–Cook hardening and damage model is adopted for the steel reinforcement; and finally, the Hashin damage model is employed for the CFRP composite material. A dynamic explicit analysis step, the CONWEP air blast model, and material definitions are implemented through the input file

The increasing threat of accidental and intentional explosions in civil and industrial infrastructure has intensified the need for structural systems with enhanced blast resistance. Structural members subjected to air-blast loads experience extremely high pressure, strain rates, and localized damage within very short durations, often leading to catastrophic failure. Consequently, simulating air-blast effects on advanced composite structural elements has become a critical area of research in protective engineering.

Composite beams combining stainless steel fiber reinforced refractory concrete (SSFRRC), normal concrete (NC), and carbon fiber reinforced polymer (CFRP) represent a promising solution for blast-resistant construction. SSFRRC offers superior high-temperature resistance, energy absorption, and crack control due to the inclusion of stainless steel fibers, making it particularly suitable for blast and fire-prone environments. Normal concrete serves as the primary load-bearing core, while externally bonded or embedded CFRP layers provide high tensile strength, corrosion resistance, and improved flexural capacity. The synergistic behavior of these materials can significantly enhance structural resilience under extreme dynamic loading.

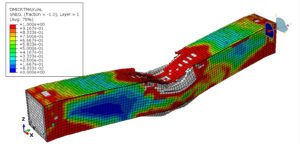

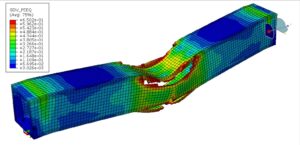

Air-blast loading is characterized by a rapidly rising peak overpressure followed by an exponential decay, often accompanied by impulse-dominated response and wave–structure interaction effects. Accurately simulating such phenomena near composite beams presents significant challenges, including the modeling of shock wave propagation, material nonlinearities, strain-rate sensitivity, and complex interfacial behavior between dissimilar materials. Numerical simulation methods, particularly finite element and coupled Eulerian–Lagrangian (CEL) or Arbitrary Lagrangian–Eulerian (ALE) approaches, are widely adopted to capture both the blast wave evolution in air and the dynamic response of structural components.

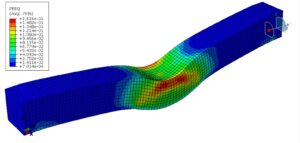

This study focuses on the numerical simulation of air-blast loads acting near an SSFRRC–NC–CFRP composite beam. Emphasis is placed on predicting pressure distribution, deformation patterns, damage evolution, and failure mechanisms under various blast scenarios. By incorporating advanced constitutive models for SSFRRC, concrete damage plasticity for normal concrete, and orthotropic damage models for CFRP, the simulation aims to provide insight into the effectiveness of hybrid composite beams in mitigating blast-induced damage. The findings contribute to the development of safer, more resilient structural systems for critical infrastructure subjected to extreme loading conditions.

This study employs ABAQUS/Explicit to simulate the response of an SSFRRC–NC–CFRP composite beam subjected to near-field air-blast loading. The analysis focuses on blast pressure distribution, global and local deformation, damage evolution, and failure mechanisms. The numerical results provide insight into the effectiveness of hybrid composite beams for blast-resistant design and support the development of optimized strengthening strategies for critical infrastructure exposed to extreme loading events

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials