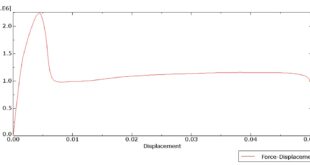

In this tutorial, Simulation Bending behavior of aluminum foam-filled double cylindrical tubes in Abaqus has been studied. During the past two decades, many research works have been done to study the axial crushing behavior of thin-walled columns, which work as energy absorption members, in order to improve their capacity. On the other hand, a study on the real-world vehicle crashes showed that up to 90% involved structural members failed in bending collapse mode. As the results obtained in many related works, empty tubes are not suitable for bearing three-point bending loads due to their very low resistance to indentation. In order to achieve higher bending resistance and weight efficiency in energy absorption, ultra-light metal fillers such as aluminum foams were filled into thin-walled structures

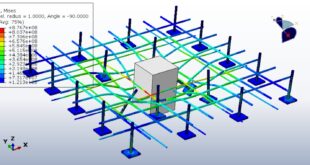

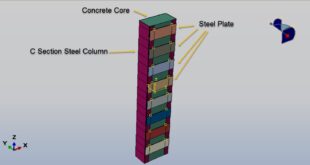

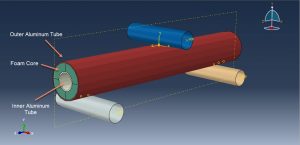

The two aluminum tube is modeled as a three-dimensional shell part and foam as a solid part. Some rigid bodies are created as a hydraulic jack and boundary area. You can see a figure of assembled parts at below

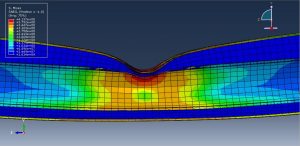

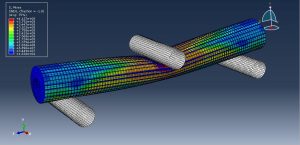

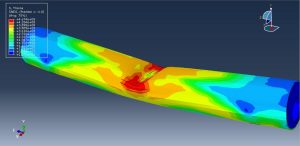

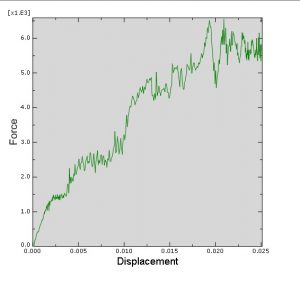

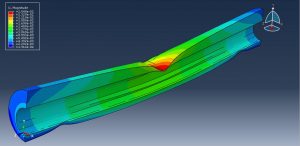

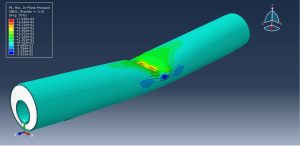

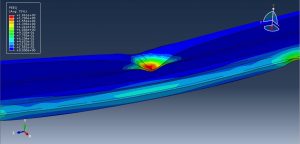

The aluminum material is modeled as an elastic-plastic material with shear, ductile, and MSFLD damage criterion with evolution. The criterion can predict tubes damage during dynamic bending. The foam material is modeled as elastic material with Crashable foam plasticity coupled with hardening data. The dynamic explicit step is appropriate for this type of analysis. The general contact algorithm with a friction coefficient as a contact property is selected. The contact among tubes and foam is considered as perfect contact. The fixed boundary condition is assigned to the bottom rigid bodies and displacement with smooth amplitude is assigned to the top rigid body. The mesh should be fine because the deformation is too high during the simulation

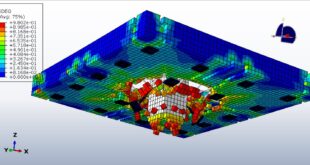

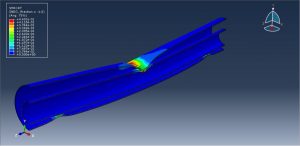

After the simulation, all results such as deformation, foam compaction, damage criterion, stress, strain,… can be achievable. You can see some figures for the result below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Nine Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials