In this tutorial, the finite element simulation of titanium foam behavior as an implant under dynamic load in Abaqus has been investigated. metal foams, new class materials, have increasingly been employed for a range of applications such as structural components, automotive parts, sound and vibration absorbers, heat exchanger and biomedical implants. This is due to their unique combination of properties such as low density, high specific stiffness, high specific strength, and good energy absorption capability. Among metal foams, titanium foams (Ti-foams) are preferred in many crucial applications including biomedical implants which biocompatibility is required. The main interests for using cellular metals come from the increase of the friction coefficient between the implant and the surrounding bone. It allows mechanical interlocking of bone with the implant by substantial bone in-growth and better long term stability. Additionally, stiffness of the implants can be tailored by varying porosity to reduce the stress shielding effect

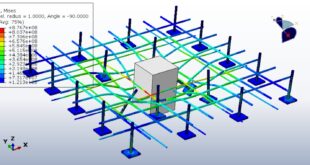

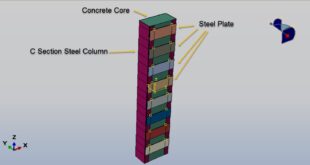

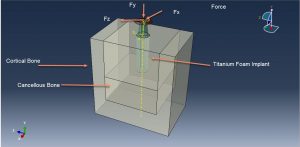

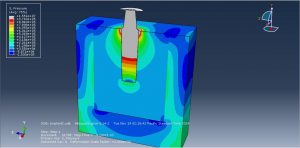

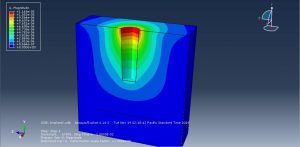

In this simulation, the titanium foam implant and mandible are modeled as three-dimensional solid parts. The mandible contains a cancellous and cortical bone. You can see a figure of the assembled parts below

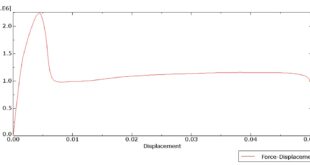

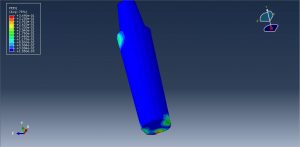

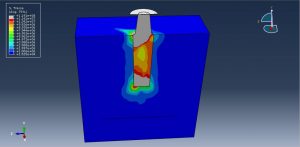

The titanium foam material is modeled as elastic with crushable foam plastic behavior. The isotropic type with hardening is used to model titanium foam material with a crushable foam model. The cancellous and cortical bone material is modeled as an elastic material. The dynamic explicit procedure is used to model dynamic load over the titanium foam. The surface to surface contact with property in the first simulation and tie constraint in the second simulation are used to model the contact zone between bone and implant. The fixed boundary condition is assumed for the bottom surface of the mandible and concentrated force is applied in three directions. The mesh should be so fine at the contact zone

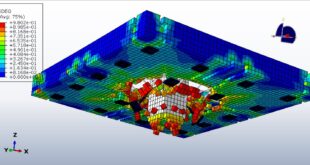

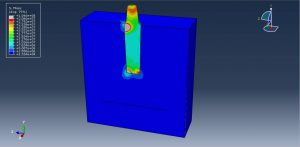

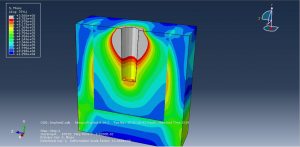

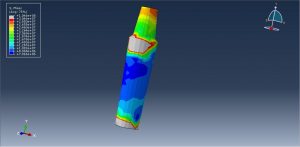

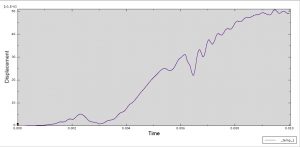

After the simulation, all results such as stress, strain, force, ….are achievable. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Thirty Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials