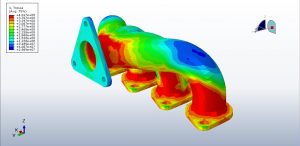

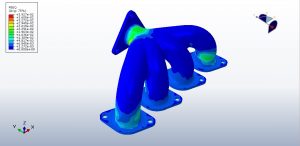

In this tutorial, the Thermal and Structural Analysis of Exhaust Manifold in Abaqus has been investigated. The manifold geometry is a complex one, so the geometry is imported to the Abaqus from SolidWorks software. You can see a figure of the manifold part below

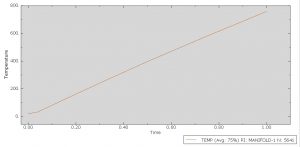

The exhaust manifold is a very essential component of an engine in the field of automobiles mounted on the cylinder of an internal consumption engine. The gases coming from the cylinder head at different exhaust strokes are collected with minimum backpressure for smooth exhaust. The gases coming from one cylinder at a particular stroke need to discharge smoothly before the gases from other strokes. From multiple pipes, gases were supplied into a common pipe before entering into the muffler. The performance of an IC engine depends upon the design of the manifold and effective emission of combustion products. The exhaust gases coming out of the engine cylinder has a temperature in the range of 800°C with a pressure range from 100kPa to

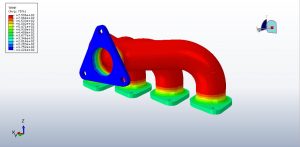

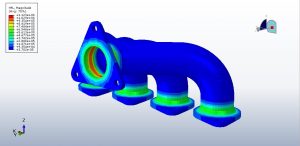

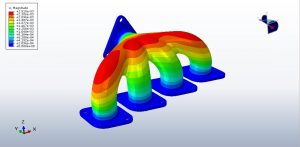

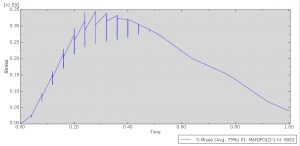

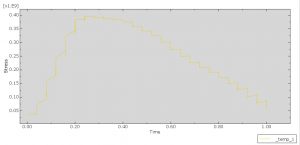

۵۰۰kPa and manifold surface experience 250°C-300°C temperature. Therefore the manifold due to temperature gradients exerts a thermal load on the material and causes displacement of the material from the mounted position with the cylinder head. When this thermal load is mapped along with the structural load due to bolt pretension the stresses will be results both on the manifold as well as bolt materials. These stresses should be within the limit for safe design. There it is necessary to do the thermo-mechanical analysis during the initial stage of the design

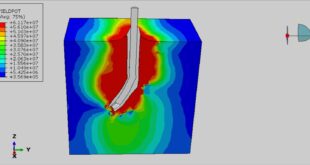

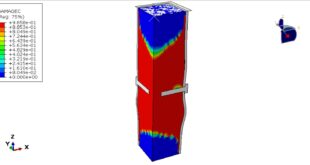

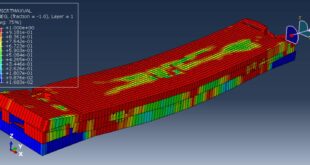

The proper material data depend on the temperature is selected for the manifold. The simulation has two sections, the first thermal analysis, and the second, stress analysis. In the first section, through a thermal step, Abaqus calculate the temperature and then through a static step, Abaqus uses that temperature to consider thermal stress. Convection and Radiation property are assigned to the internal surfaces. The proper boundary condition for both sections is considered. The mesh should be fine to obtain correct results. After the simulation, all results for the thermal and stress analysis are available. You can see some figures for the results below

You can provide CAE, INP, and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning the process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment, send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials