Super-austenitic stainless steels (SASS), distinguished by their high alloy content and superior corrosion resistance, have emerged as promising materials for blast-resilient structures operating in harsh marine environments. When configured as sandwich panels with metallic face sheets and lightweight cores, they offer a favorable combination of strength, ductility, and energy absorption. These attributes make SASS sandwich systems attractive for naval, offshore, and protective applications, where structures may be subjected to impulsive loading

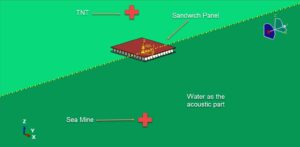

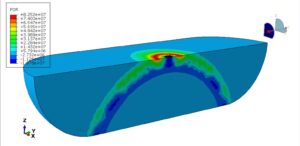

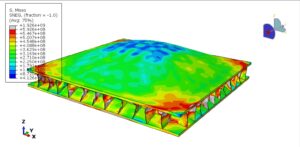

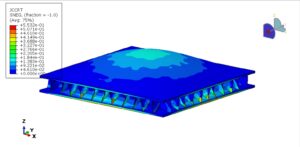

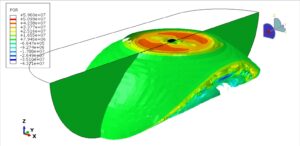

In this simulation, the analysis of super-austenitic stainless steel panels under air blast and underwater explosion in Abaqus has been done. The two steel plates and the sandwich core are modeled as three-dimensional parts. You can see a figure of the assembled parts below

Air blast and underwater explosion (UNDEX) events impose intense, short-duration pressure pulses that drive complex, rate-dependent deformation mechanisms in metallic sandwich panels. The response of SASS-based systems is influenced by the intrinsic high-rate plasticity of the alloy, the interaction between face sheets and core, and the distinct characteristics of loading in air versus water. Air blasts typically cause localized face-sheet yielding and core crushing, whereas UNDEX loading—amplified by fluid–structure interaction—can result in larger global deflections, extended impulse transmission, and more severe through-thickness damage. Understanding the deformation behavior of super-austenitic stainless steel sandwich panels under these extreme conditions is essential for optimizing their structural performance and guiding the design of next-generation blast- and shock-resistant systems

To model steel material under both air blast and underwater explosion conditions simultaneously, the Johnson-Cook hardening and damage models are employed. A dynamic explicit step, CONWEP as the air blast method, and UNDEX method as the underwater explosion are selected. The proper boundaries and meshes are applied to all parts

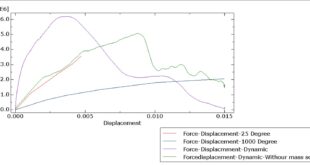

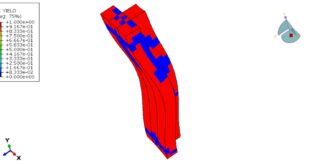

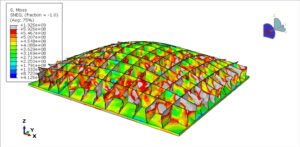

After the simulation, all results such as stress, strain, pore pressure, damage, deformation, and… are available. You can see some figures of the results below

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials