Reinforced concrete (RC) flat slabs are widely used in modern building construction due to their architectural flexibility, reduced story height, and simplified formwork. However, one of the most critical failure modes of flat slabs is punching shear, which occurs in the vicinity of slab–column connections. Punching failure is typically brittle and characterized by the formation of inclined shear cracks that propagate around the loaded area, leading to sudden loss of load-carrying capacity with limited warning. This vulnerability becomes more severe under low-velocity impact loading, where high strain rates, stress concentrations, and localized damage significantly influence the structural response

Traditional strengthening techniques—such as shear studs, stirrups, or fiber-reinforced polymers—primarily enhance static punching resistance but may not provide sufficient energy dissipation under impact conditions. In recent years, shape memory alloys (SMAs), particularly superelastic Ni–Ti (Nickel–Titanium) alloys, have attracted attention in structural engineering applications due to their unique ability to undergo large reversible strains and dissipate energy through stress-induced phase transformation. The superelastic behavior of Ni–Ti enables substantial hysteretic energy dissipation and self-centering capability, making it a promising reinforcement material for improving impact resistance and ductility of RC slabs

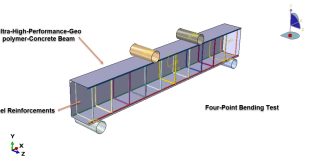

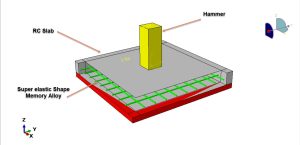

You can see a figure of the assembled parts below

Under low-velocity impact, the punching shear capacity of an RC flat slab is governed by complex interactions among inertia effects, strain-rate sensitivity of concrete, cracking evolution, reinforcement yielding, and contact forces. The incorporation of superelastic Ni–Ti reinforcement modifies this behavior by

Enhancing energy absorption through phase transformation

Reducing residual deformations due to self-centering effects

Delaying crack propagation and mitigating brittle punching failure

Improving post-impact integrity of the slab–column connection

To accurately capture these mechanisms, advanced nonlinear finite element modeling is required. In this study, numerical simulations are performed using Abaqus finite element software. The concrete slab is modeled using the Concrete Damaged Plasticity (CDP) constitutive model, which accounts for stiffness degradation under tensile cracking and compressive crushing, as well as strain-rate effects when incorporated appropriately. The superelastic Ni–Ti reinforcement is defined using a material model that represents stress-induced martensitic transformation and reverse transformation upon unloading, enabling simulation of its nonlinear hysteretic response. A Dynamic Explicit analysis step is adopted to effectively handle impact contact, severe nonlinearities, and short-duration transient response.

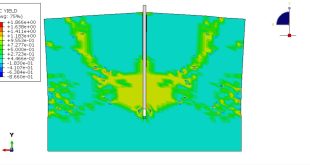

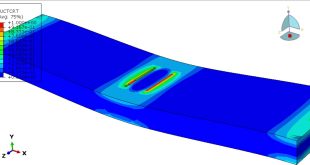

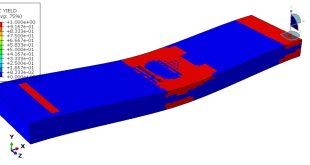

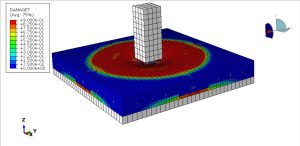

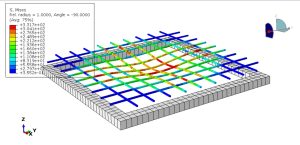

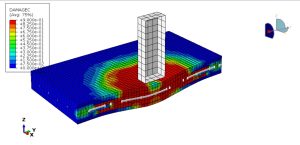

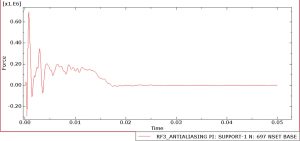

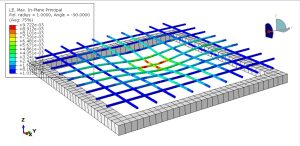

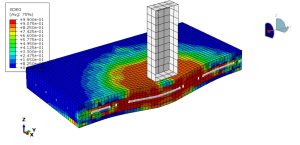

The objective of this investigation is to evaluate the punching shear capacity and failure mechanisms of RC flat slabs reinforced with superelastic Ni–Ti under low-velocity impact loading. Particular attention is given to load–time response, impact force history, energy dissipation, crack patterns, damage evolution, and residual deformation. The study aims to provide insight into the effectiveness of superelastic Ni–Ti reinforcement in mitigating brittle punching failure and enhancing impact resilience of flat slab systems. After the simulation, all results such as stress, strain, tension damage, compression damage, stiffness degradation, and … are available. You can see some figures of the results below

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials