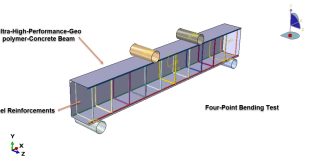

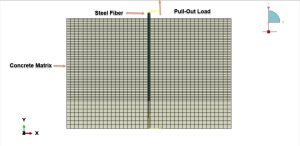

The pull-out behavior of steel fibers embedded in concrete is a fundamental mechanism governing the post-cracking performance, toughness, and ductility of fiber-reinforced concrete (FRC). When cracks initiate and propagate, the bridging action provided by steel fibers transfers stresses across crack faces, enhancing energy absorption capacity and residual strength. Therefore, understanding and accurately predicting the pull-out response of a single steel fiber is essential for evaluating bond performance and improving composite design. The pull-out test is widely used to characterize the interfacial bond behavior between a steel fiber and the surrounding concrete matrix. During the test, a single embedded fiber is subjected to a tensile displacement until complete debonding and extraction occur. You can see a fiure of the assembled parts below

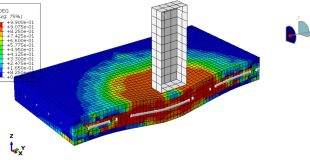

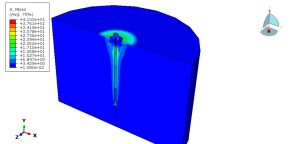

Due to the complexity of the fiber–matrix interaction, nonlinear finite element modeling provides an efficient approach for simulating the pull-out response. In this study, numerical simulations were conducted using ABAQUS to investigate the bond behavior between a steel fiber and concrete under monotonic pull-out loading

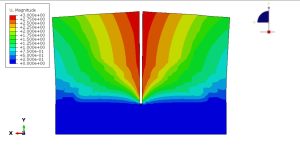

A 2D model provides a computationally efficient representation of the pull-out test. It simplifies the geometry while capturing the essential mechanics of interfacial debonding and slip. This approach is particularly useful for parametric studies and preliminary investigations of bond characteristics

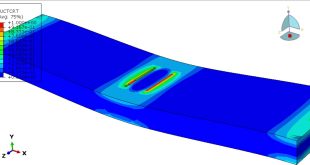

The axisymmetric model represents the cy

lindrical geometry of the fiber and the surrounding concrete more realistically. Assuming symmetry around the fiber axis, this approach reduces computational cost compared to full 3D modeling while maintaining higher geometric accuracy than a simplified 2D plane model. It is especially suitable for straight fibers with uniform embedment

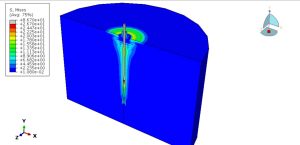

The concrete matrix was modeled using the Concrete Damaged Plasticity (CDP) model available in ABAQUS. The CDP model captures

Nonlinear compressive behavior, Tensile cracking, and stiffness degradation, Damage evolution under monotonic loading

This constitutive formulation allows accurate representation of cracking and crushing phenomena occurring near the fiber–matrix interface during pull-out

The steel fiber was modeled as a linear elastic material due to its high stiffness and limited plastic deformation relative to concrete in pull-out scenarios

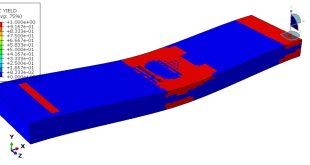

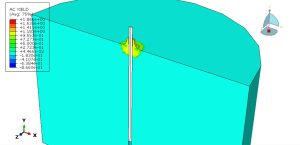

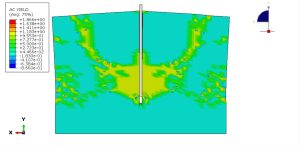

The interaction between the steel fiber and concrete was defined using a cohesive interaction formulation. This approach allows simulation of

Initial bonded behavior, Damage initiation based on traction criteria, Progressive damage evolution, and Complete debonding and frictional sliding

A general static step was employed to simulate quasi-static loading conditions consistent with experimental pull-out testing. Displacement-controlled loading was applied to the free end of the fiber, ensuring stable convergence during the softening and debonding phases

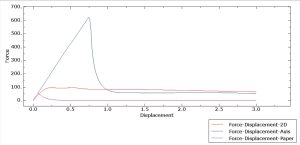

By comparing 2D and axisymmetric modeling approaches, the study evaluates the influence of geometric assumptions on predicted bond strength, stiffness, and failure mechanisms

Such numerical investigations contribute to improved understanding of fiber–matrix interaction mechanisms and guide for optimizing steel fiber design and embedment characteristics in fiber-reinforced concrete systems

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials