Interlocking masonry constructed from rubberized concrete represents a sustainable alternative to traditional masonry systems, offering benefits such as reduced material waste, improved deformability, and enhanced energy absorption. The incorporation of recycled rubber into concrete alters its mechanical behavior, introducing nonlinear characteristics that influence the performance of interlocking block assemblies under vertical loading

Due to the complexity of material nonlinearity, contact interactions, and potential failure mechanisms, analytical approaches alone are insufficient for accurately evaluating structural response. Finite Element Analysis (FEA) provides an effective means to model these behaviors. Abaqus, with its advanced nonlinear capabilities and the Concrete Damaged Plasticity (CDP) model, allows for the realistic simulation of cracking, crushing, contact interaction, and load transfer within masonry units

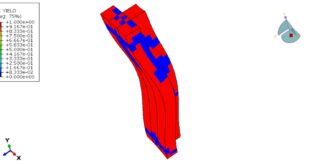

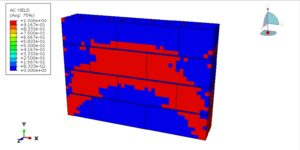

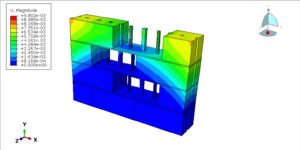

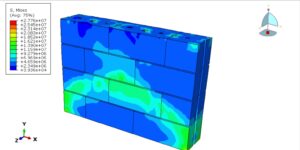

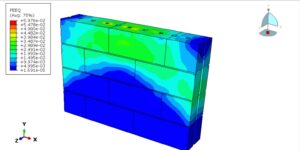

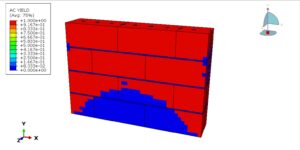

Finite element modeling of rubberized concrete interlocking masonry under vertical loading offers valuable insight into stress distribution, deformation patterns, and failure modes. These analyses support the optimization of block design, material composition, and overall system performance, contributing to the development of more sustainable and resilient masonry construction practices

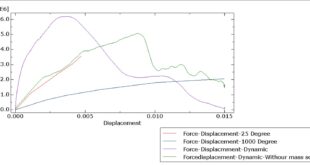

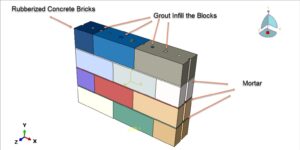

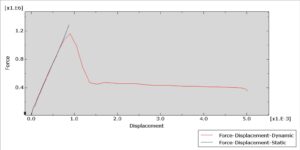

In this example, all parts, such as rubberized blocks, mortar, and grouts, are modeled as three-dimensional solid parts. The concrete Damage Plasticity material model is selected to demonstrate the correct behavior of all members under axial load. Both dynamic and static steps are used to make a comparison between them. The proper mesh, interactions, and boundaries are assigned to all parts. After the simulation, all results such as stress, strain, displacement, force-displacement diagram, and … are available. You can see some figures of the results below

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials