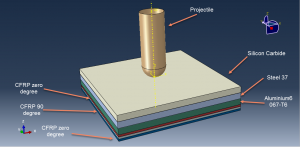

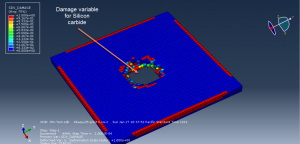

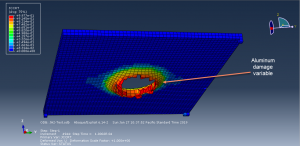

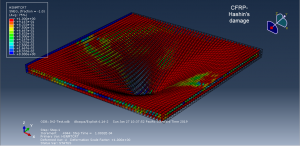

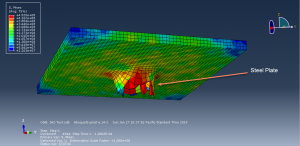

The study of interaction between two impacting bodies, known as impact dynamics or terminal ballistics has many crucial applications. Bullet impact on armor, occupant and pedestrian safety during automobile accidents, tool drop on aircraft wing, are few examples where impact dynamics plays an important role. An in-depth understanding of deformation behavior of materials under impact loading helps not only in designing better products but more importantly saving human life. Knowledge of material response under impact loading will help in estimating, enhancing and extending life and performance of any structure. Impact dynamics broadly depends upon two primary variables, namely the geometry and material of impacting bodies. Most often geometry of the impacting bodies gets dictated by the design parameters other than impact requirements: an aircraft wing has to be of an aero foil configuration, an armor has to be the shape of human body with limited thickness to enable mobility in combat zone, and a bullet has to be of conical shape for effective penetration and so on. Ultimately, it boils down to the response of material(s), which dictates the performance of the structure under impact loading. Various theories have been proposed to model the average behavior of metals, composites and ceramics under impact loading. Depending upon their nature, different materials have found their niche domain of application. While ceramic materials are most commonly used as front layer in armor for protection against bullet and shrapnel due to their high penetration resistance capability, epoxy and epoxy-based composites are ubiquitous in automobile industry for energy absorption due to high strain to failure and hyper-elastic nature. Domain dependent application of materials is most common solution strategy for any design engineer and some kind of saturation in material choice has been reached recently in this regard. None the less it is well understood that these solutions are not extremal and further performance enhancement in the form of weight reduction or/ and higher level of energy absorption is possible with intelligent design approach.In this simulation silicon carbide,steel,aluminium and three CFRP layouts are use as sandwich panel under rigid impact which you can see a figure of assembled parts at below

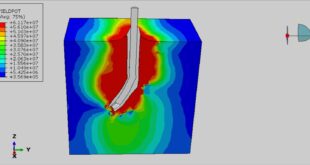

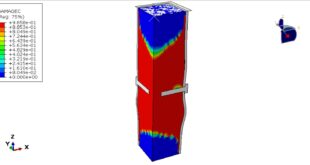

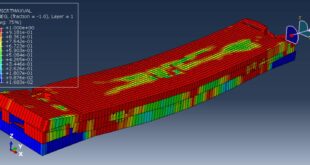

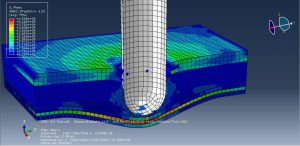

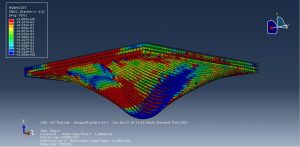

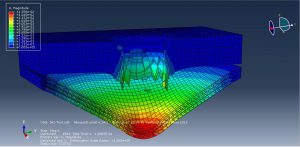

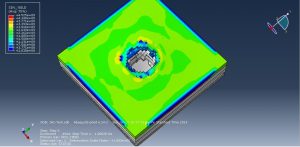

Finite element (FE) simulations using Abaqus/Explicit are performed to study the deformation behavior of .materials under impact loading Terminal ballistics between two solid bodies induces extremely high pressure and temperatures around the impact interface for a very short duration. These extreme conditions cause shock waves which eventually decay to elastic waves at large distances. In this short duration, the material may undergo physical changes such as melting or evaporation as well as mechanical changes which leads to loss of strength, local fracture and total shattering. Even though this state of material is irreversible one, the state of thermodynamic equilibrium is maintained. The material properties in this terminal ballistic belong either to equation of state: which accounts for material compression at high pressure and temperature or to the constitutive relation. Aluminium and steel material are modeled by Jonson-Cook plasticity and damage, CFRP by Hashin’s damage criterion and silicon carbide by Johnson-Holmquist(JH2).Dynamic explicit step and surface to surface contact has been used .During the analysis projectile penetrated into the sandwich panel and causes a huge deformation. You can some figures about the result at below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Seven Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials