Introduction to Bullet Ballistic Impact on Hybrid Fiber-Reinforced Concrete (HFRC) Reinforced with CFRP Sheets

Background

Hybrid Fiber-Reinforced Concrete (HFRC) combines different types of fibers (e.g., steel, polypropylene, basalt, or glass) to enhance mechanical properties such as tensile strength, ductility, and impact resistance. When further reinforced with Carbon Fiber-Reinforced Polymer (CFRP) sheets, the composite structure gains additional strength, stiffness, and energy absorption capacity, making it suitable for ballistic and blast-resistant applications

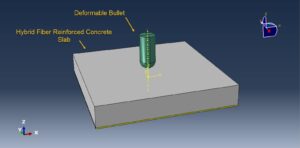

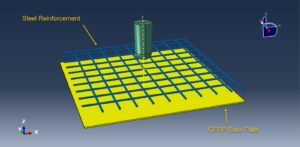

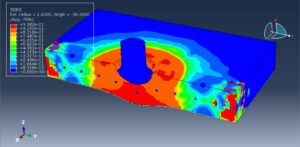

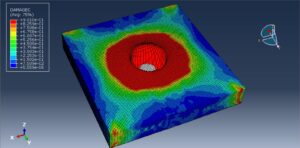

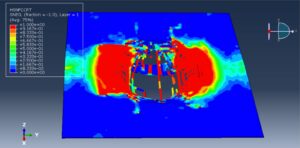

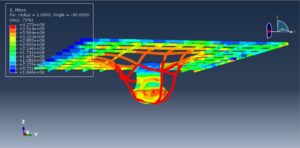

The HFRC and bullet are modeled as three-dimensional solid parts. The steel reinforcements are modeled as a wire part. The CFRP sheet with some layers is modeled as a shell part. You can see the figures of the assembled parts below

Ballistic Impact on HFRC-CFRP Composites

When a high-velocity projectile (e.g., a bullet) strikes HFRC reinforced with CFRP, several mechanisms come into play

Initial Impact and Stress Wave Propagation

The bullet transfers kinetic energy to the target, generating stress waves

The CFRP sheet (externally bonded or embedded) helps distribute the impact load over a larger area, reducing localized damage

Fiber Activation and Crack Arrest

The hybrid fibers in HFRC (e.g., steel for strength, synthetic fibers for bridging microcracks) delay crack propagation

CFRP sheets provide additional tensile resistance, preventing spalling and scabbing on the rear face

Energy Dissipation Mechanisms

Fiber Pull-out: Fibers absorb energy by debonding and pulling out from the matrix

Delamination in CFRP: The layered CFRP may delaminate, dissipating energy through interfacial friction

Bullet Deformation & Fragmentation: The projectile may deform or break up, reducing penetration depth

Failure Modes

Penetration: Partial or complete perforation, depending on impact velocity and material thickness

Localized Crushing: Near the impact zone, concrete may crush, while fibers hold the structure together

CFRP Tearing: If the bullet perforates, the CFRP may exhibit fiber breakage or shear failure

Factors Influencing Ballistic Performance

Fiber Type & Hybridization: A combination of high-strength (steel) and high-ductility (polypropylene) fibers improves multi-hit resistance

CFRP Layup & Bonding: Multiple CFRP layers or cross-ply configurations enhance energy absorption

Projectile Characteristics: Bullet shape, velocity, and hardness affect penetration behavior

Concrete Matrix Strength: High-strength concrete with fine aggregates resists shattering better

Applications

Military bunkers, blast-resistant walls, and protective shelters

Military bunkers, blast-resistant walls, and protective shelters

HFRC reinforced with CFRP sheets offers superior ballistic resistance compared to conventional concrete. The hybrid fibers and CFRP work synergistically to absorb impact energy, reduce cracking, and prevent catastrophic failure. Further research can optimize fiber combinations, CFRP thickness, and bonding techniques for enhanced protection

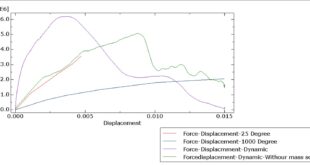

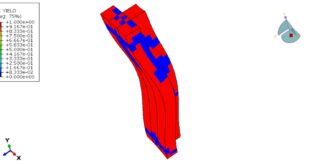

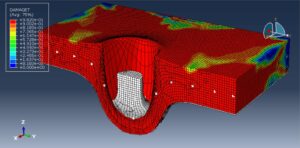

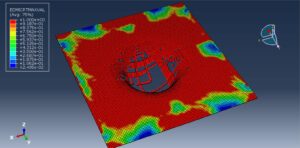

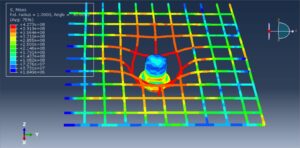

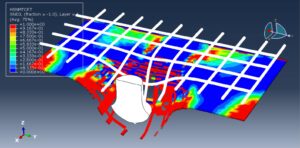

After the simulation, all results such as stress, strain, CFRP damage, failure, tension and compression damage, and others are available. You can see a figure for the results below

You can provide this simulation’s CAE, INP, and English video files here. The price of these files is Twenty-Six Euros. You can click on the button below to begin the process

Our Payment methods are: Tether, Bitcoin, TRX, PayPal, Visa, or Mastercard. Just before payment, send us an email to this address: abaqusfem.com@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials