Flat reinforced concrete slabs are widely used in building construction due to their architectural flexibility, reduced story height, and simplified formwork. However, their structural performance is often governed by punching shear failure at slab–column connections. This failure mode is brittle, occurs with little warning, and can lead to progressive collapse. Enhancing the punching resistance of flat slabs, therefore, remains a critical research and design objective

Normal-strength concrete (NSC) slabs typically exhibit limited tensile capacity and crack resistance. Once flexural cracking develops around the column region, stresses concentrate along a truncated cone or pyramid failure surface, ultimately resulting in punching shear failure. Conventional strengthening methods—such as increasing slab thickness, adding shear reinforcement, or using drop panels—are often impractical in retrofit scenarios due to architectural and construction constraints

The rational use of Ultra-High-Performance Fiber-Reinforced Concrete (UHPFRC) offers an efficient alternative for improving punching performance. UHPFRC is characterized by

Very high compressive strength (>120 MPa typically)

Strain-hardening tensile behavior

High fracture energy and crack-bridging capacity from steel fibers

Superior bond with existing concrete substrates

When applied locally in the column vicinity (e.g., overlays, jackets, or embedded layers), UHPFRC can significantly enhance

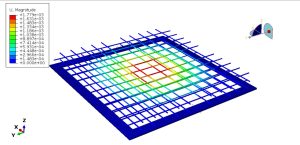

Crack control and stiffness

Shear transfer mechanisms

Ductility and energy absorption

Overall punching shear capacity

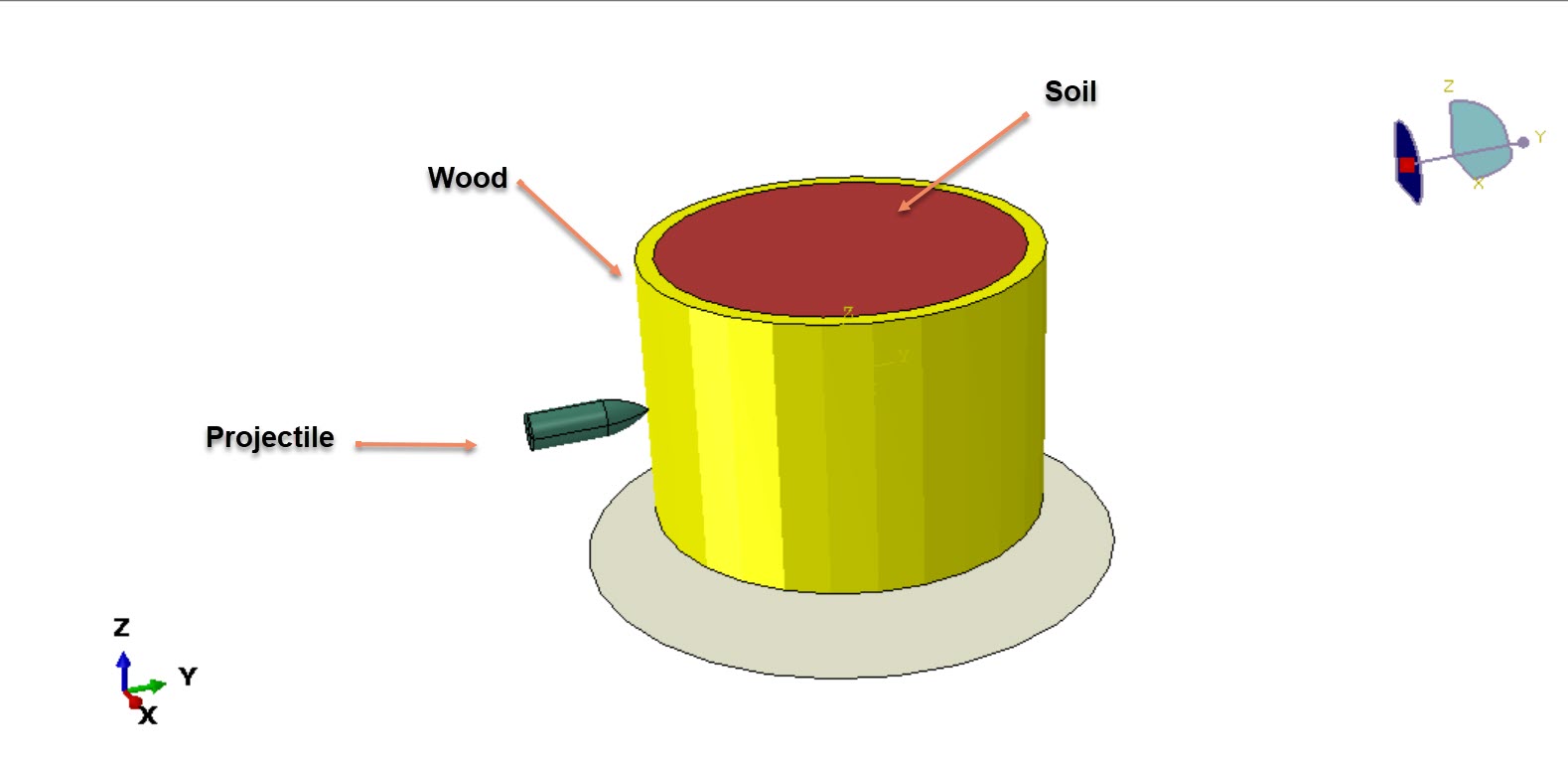

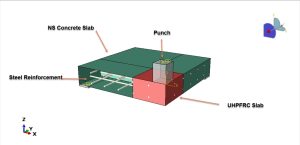

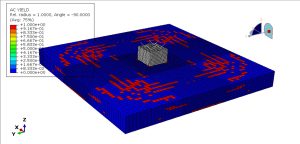

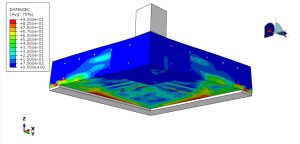

You can see a figure of the assembled parts below

Both NSC and UHPFRC are simulated using the Concrete Damaged Plasticity (CDP) model in Abaqus. For NSC, the response is typically brittle in tension with softening after cracking. An accurate definition of tension damage evolution is critical for reproducing punching mechanisms

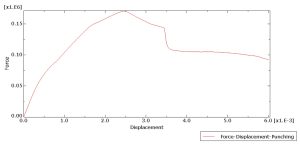

The punching response of NSC–UHPFRC composite slabs can be understood through evolving load-transfer stages

Elastic Stage

Load is transferred primarily through flexural action. Stresses remain below cracking limits

Cracking Initiation

Radial and circumferential cracks form around the column. UHPFRC layers delay crack opening due to fiber bridging

Post-Cracking Redistribution

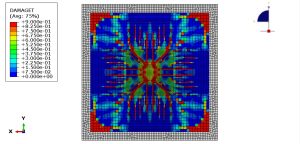

Damage Localization

In NSC slabs, a critical shear crack develops rapidly. With UHPFRC strengthening, crack propagation is more distributed, increasing ductility

Punching Failure

Failure occurs along an inclined surface. UHPFRC modifies the failure geometry, often enlarging the critical perimeter and increasing peak load

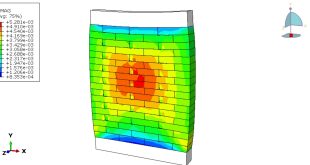

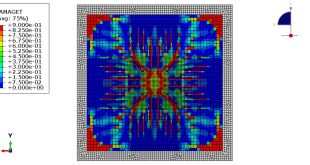

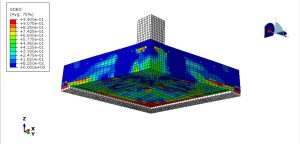

After the simulation, all results are available. You can see some figures of the results below

You can provide this simulation’s CAE, INP, and English video files here. The price of these files is Thirty Euros. You can click on the button below to begin the process

Our Payment methods are: Tether, Bitcoin, TRX, PayPal, Visa, or Mastercard. Just before payment, send us an email to this address: abaqusfem.com@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials