Introduction to Modeling Steel Beam-to-CFDST Column Connection with Bolts

Overview of CFDST Columns and Steel Beam Connections

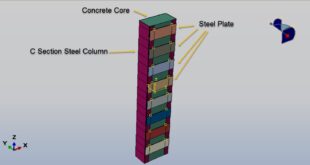

Concrete-Filled Double-Skin Steel Tubular (CFDST) columns consist of two concentric steel tubes with concrete sandwiched between them. These columns offer high strength, ductility, and excellent seismic performance. When connecting a steel beam to a CFDST column using bolts, the modeling approach must account for

Load transfer mechanisms (axial, shear, moment)

Bolt behavior (pre-tension, slip, bearing, shear failure)

Concrete-steel interaction (confinement, local buckling)

Connection detailing (end-plate, angle cleats, or T-stubs)

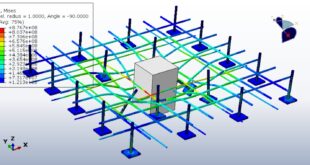

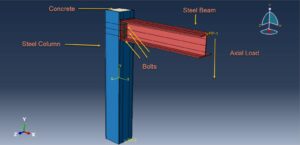

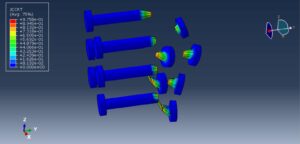

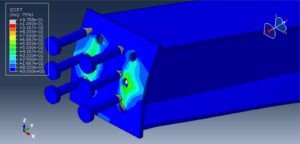

All parts, such as bolts, steel beam, steel column, and concrete, are modeled as three-dimensional solids. You can see a figure of the assembled parts below

Key Modeling Considerations

Finite Element Modeling (FEM) Approach

Material Nonlinearity: Define steel (beam, column, bolts) with bilinear or multilinear hardening. Concrete should use a damage plasticity model (e.g., CDP in ABAQUS)

Contact Interactions

Bolt-to-hole friction (Coulomb friction model)

Steel-concrete interface (bond-slip behavior)

Boundary Conditions & Load Application

Fixed column base, cyclic/displacement-controlled beam loading for seismic analysis

Challenges in Modeling

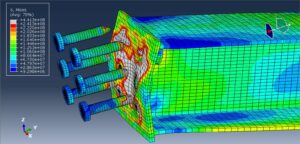

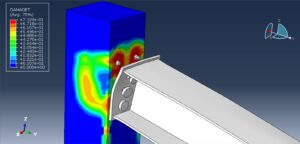

Local effects: Bolt prying, concrete crushing near the connection

Mesh sensitivity: Refined meshing is needed at stress concentrations

Validation: Experimental data or code-based checks (AISC, Eurocode) are essential

Modeling steel beam-to-CFDST column bolted connections requires a balance between accuracy and computational efficiency. A mix of detailed FEM and analytical methods ensures reliable predictions for design and assessment

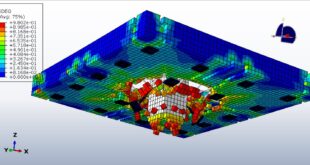

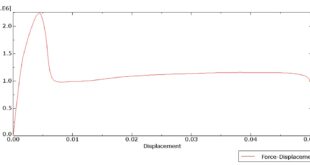

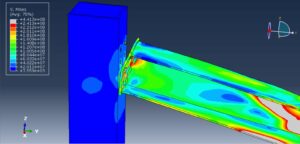

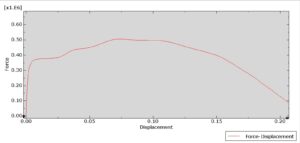

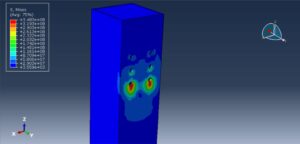

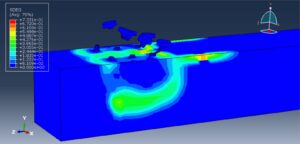

After the simulation, all results such as stress, strain, bolt failure, force-displacement diagram, tension, compression damage, deformation, and others are available. You can see a figure of the assembled parts below

You can provide this simulation’s CAE, INP, and English video files here. The price of these files is Twenty-Six Euros. You can click on the button below to begin the process

Our Payment methods are: Tether, Bitcoin, TRX, PayPal, Visa, or Mastercard. Just before payment, send us an email to this address: abaqusfem.com@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials