Flexural Behavior of Adhesively Bonded Cross-Laminated Timber–Ultra-High-Performance Concrete (CLT-UHPC) Composite Panels

Introduction

Composite structural systems combining cross-laminated timber (CLT) and ultra-high-performance concrete (UHPC) have gained attention due to their potential to enhance structural efficiency, sustainability, and performance. CLT provides a high strength-to-weight ratio, carbon sequestration benefits, and ease of prefabrication, while UHPC contributes exceptional compressive strength, durability, and stiffness. When adhesively bonded, these materials form a high-performance composite panel suitable for floors, bridge decks, and prefabricated building components

The flexural behavior of CLT-UHPC composite panels is critical for structural design, influencing load capacity, stiffness, ductility, and failure modes. This discussion examines key aspects of their flexural performance, including

Composite action and interfacial bond strength

Failure mechanisms under bending

Influence of material properties and adhesive selection

Comparative advantages over traditional materials

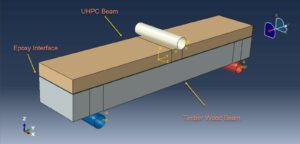

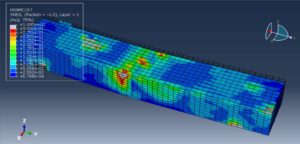

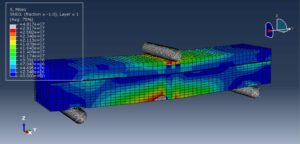

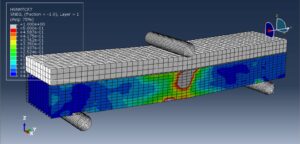

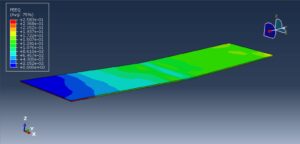

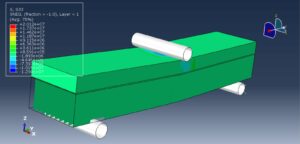

The UHPC and timber beam are modeled as three-dimensional solid parts. The epoxy glue as the interface is modeled as a three-dimensional solid part with a thin thickness. You can see a figure of the assembled parts below

Composite Action and Bonding Mechanism

The flexural performance of CLT-UHPC composites depends on the degree of composite action achieved through adhesive bonding. Two primary interaction levels exist

Full composite action: The adhesive bond prevents slip, allowing the CLT and UHPC to act as a unified section that increases stiffness and strength

Partial composite action: Slip occurs at the interface, reducing efficiency but improving ductility

Key Factors Affecting Bond Performance

Adhesive type: Epoxy, polyurethane, or acrylic-based adhesives with high shear strength and durability

Surface preparation: Roughening or treatment of UHPC and CLT surfaces to enhance mechanical interlock

Curing conditions: Proper curing of adhesive to ensure long-term bond integrity

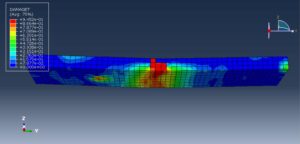

Flexural Failure Modes

Under bending loads, CLT-UHPC composite panels may experience several failure mechanisms

Tensile failure in CLT: The bottom timber layers reach their tensile strength limit

Compressive crushing of UHPC: The UHPC layer fails in compression at the top

Adhesive bond failure: Delamination or shear failure at the CLT-UHPC interface

Shear failure in CLT: Rolling shear or interlaminar shear in cross-laminated layers

The dominant failure mode depends on material thicknesses, adhesive strength, and loading conditions

Adhesively bonded CLT-UHPC composite panels offer a promising solution for sustainable, high-performance structural systems. Their flexural behavior is governed by material properties, adhesive performance, and interfacial bond strength. Further research is needed to optimize design methodologies and ensure long-term reliability in real-world applications

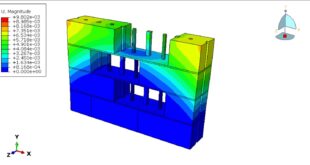

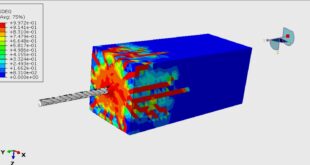

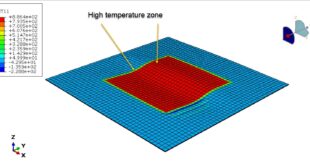

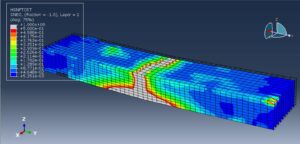

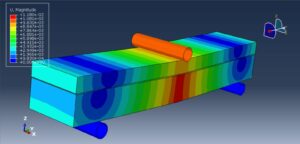

After the simulation, all results such as stress, strain, damage, failure, force-displacement diagram, and others are available for all parts. You can see some figures for the results below

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials