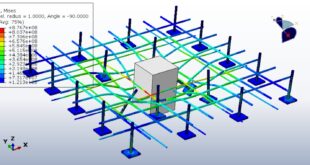

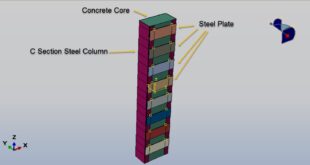

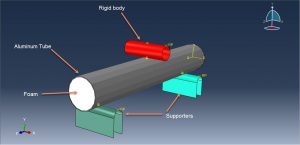

In this tutorial, Simulation three points bending of the foam-filled aluminum tube under dynamic load in Abaqus has been studied. The foam is modeled as a three-dimensional solid part and the aluminum tube is modeled as a three-dimensional shell part. Three rigid bodies are used as a pusher and supporters. You can see a figure of the assembled parts at below

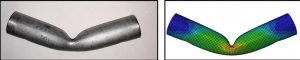

In passenger cars, the side impact beam is used as the crashworthy structure which strengthens the door of the vehicle and protects passengers from side collisions. Aluminum alloy tubes are mostly used as side-impact beam because of their improved strength to weight ratios which is a key factor for the fule economy. Mostly metallic circular cylindrical aluminum alloy tubes are used as energy absorbers because of low weight and ease of the manufacturing process. The severity of the side collision in the passenger cars can be reduced by increasing the load-carrying capacity and energy absorption characteristics of the aluminum alloy tube

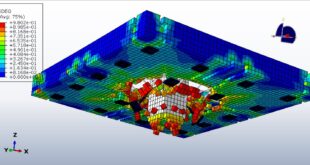

To model aluminum behavior under dynamic bending, elastic-plastic property with ductile, shear and MSFLD damage is used. These parameters will provide a good behavior of aluminum if damage happens in the model. To model foam behavior, crashable foam plasticity with hardening is used. The dynamic explicit procedure is appropriate for this type of analysis. The contact between the aluminum tube and the foam is considered as a perfect contact. The surface to surface contact with property is considered for the rigid bodies contact with the aluminum tube. The fixed boundary condition is assigned to the bottom rigid bodies and displacement is assigned to the upper rigid body. This simulation needs a fine mesh to reflect good and proper results

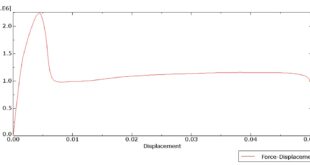

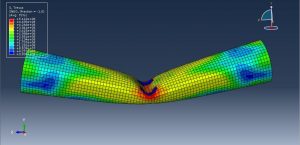

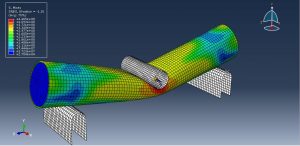

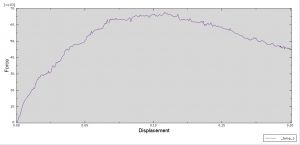

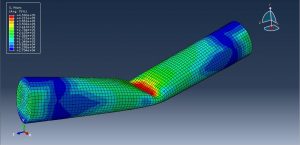

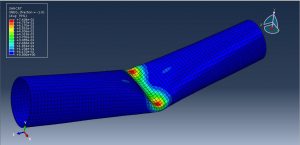

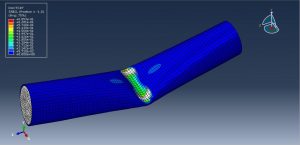

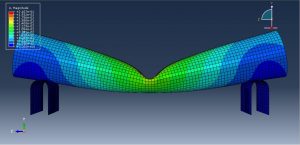

After the simulation, you can see the deformation for the aluminum tube and foam compaction under bending load. The damage variable can be achievable for the aluminum tube. You can see some figures for the result below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials