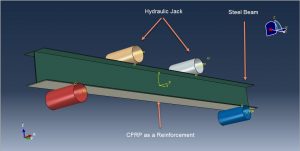

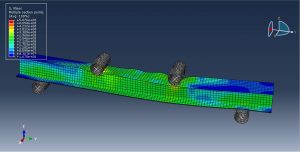

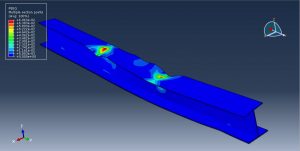

In this tutorial, the Simulation flextural behavior of the steel beam reinforced with CFRP in Abaqus has been investigated. The steel beam and CFRP sheet are modeled as three-dimensional shell parts. The rigid bodies are modeled as a discrete rigid body. You can see a figure of the assembled parts at below

Fiber-reinforced polymer (FRP) materials are composite materials contain an epoxy matrix and fiber polymer. These FRP materials are being widely used as alternative materials for the rehabilitation and strengthening of concrete structures. The beneficial characteristics of FRP materials are high strength-to-weight ratio, corrosion resistance, and high fatigue resistance. Common FRP composite materials used in rehabilitation and strengthening are Glass FRP (GFRP), Carbon FRP (CFRP), and Aramid FRP (AFRP). Several studies have been conducted on strengthening and rehabilitation of steel beams using CFRP composite materials. The major drawbacks of using CFRP for rehabilitation and strengthening of a steel structure are its brittle failure modes and the possibility of galvanic corrosion.

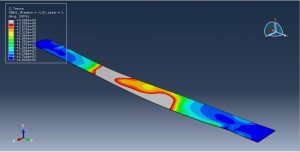

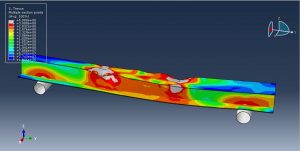

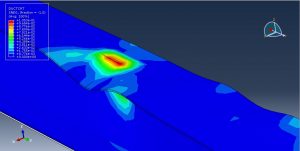

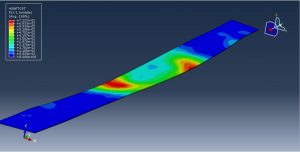

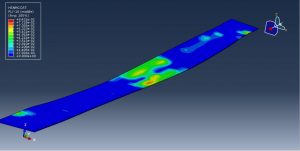

The steel material with elastic-plastic behavior coupled with ductile damage criterion for the beam and elastic data as an engineering constant couple with Hashin’s damage criterion for the CFRP is used. These material models can predict the damage during the static stimulation and bending load. The general static stimulation with some changes in the convergence model is used. The surface to surface contact with contact property is used amonge rigid parts with steel beam and CFRP. The perfect contact is assumed between the steel beam and CFRP. The fixed boundary conditions are assigned to the bottom rigid bodies. The load as displacement is assigned to the two top rigid bodies. The mesh should be fine to obtain the proper results

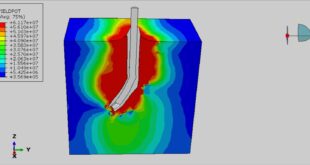

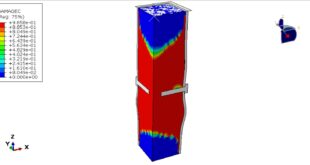

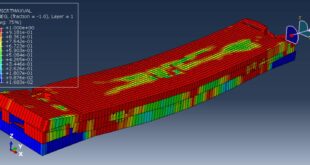

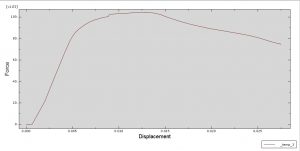

After the simulation, all results such as stress, strain, damage, and Force-Displacement diagram are achievable. Base on the Force-Displacement diagram, the maximum force capacity is obtainable. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Five Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials