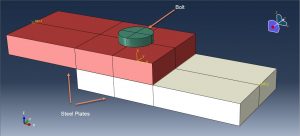

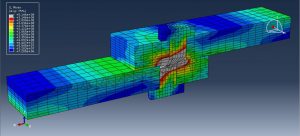

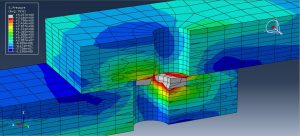

In this tutorial, simulation of bolt failure in the bolted joints in Abaqus has been done. The two steel plates and the bolt are modeled as a three-dimensional solid part. You can see a figure of the assembled parts at below

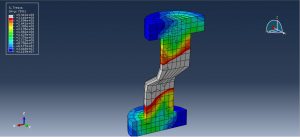

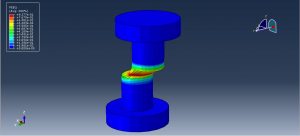

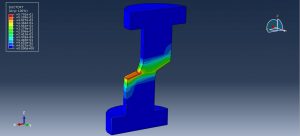

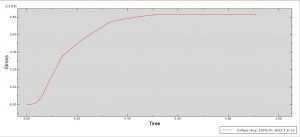

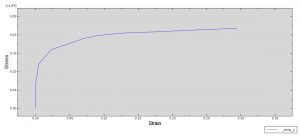

To obtain failure, the ductile damage criterion is used for all part. The steel material with elastic-plastic behavior is implied. By using the ductile criterion, Abaqus can predict the damage zone and failure area under the tension load. This analysis can be done with two static and dynamic procedures. In this tutorial static procedure is used as a general static step. To avoid early not convergence, some changes are applied in the static step. The surface to surface contact with the contact property is assigned to the contact domain. The symmetry boundary is assigned to the side surfaces of the plate. The displacement boundary is applied to the end of the plates to observe the shear failure of the bolt. The should be fine around the contact area.

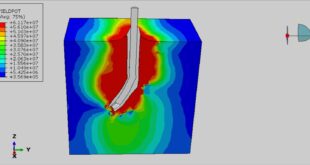

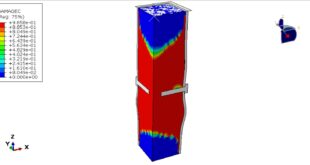

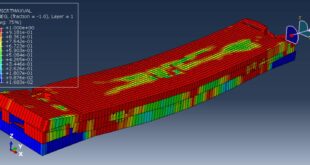

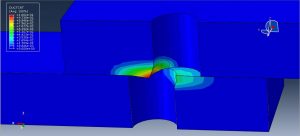

After the analysis, the damage, failure, stress, and strain are obtainable. By applying tension, the failure happened in the middle of the bolt. You can see the results of the simulation at below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials