Introduction to Pull-out Test Analysis of a Hooked GFRP Bar Embedded in Timber with Epoxy Interface

Background and Significance

Fiber-reinforced polymer (FRP) bars, particularly glass-FRP (GFRP), are increasingly used as reinforcement in timber structures due to their high strength-to-weight ratio, corrosion resistance, and compatibility with wood. However, the bond behavior between GFRP bars and timber is critical for structural performance. The pull-out test is a common experimental method to evaluate the bond strength and interfacial characteristics between the reinforcing bar and the surrounding material (in this case, timber with an epoxy adhesive interface)

When the GFRP bar has a hooked end, the mechanical interlock enhances bond resistance, making the analysis more complex than straight bars. The epoxy resin further influences load transfer, failure modes, and bond-slip behavior

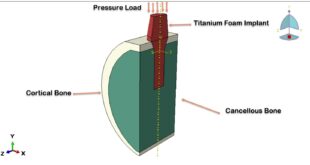

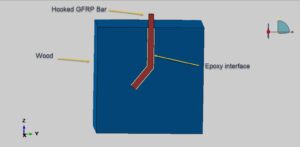

In this example, all the parts, such as timber, epoxy, and the GFRP bar, are modeled as three-dimensional solids. The epoxy is used as the interface between the hooked bar and the wood. You can see a figure of the assembled parts below

Objectives of Pull-out Test Analysis

The analysis aims to

Determine the bond strength between the hooked GFRP bar and timber

Evaluate the failure mechanisms (e.g., timber splitting, epoxy debonding, bar pull-out, or rupture)

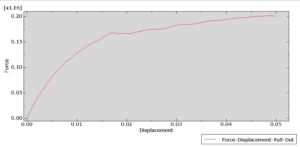

Study the load-slip relationship to understand interfacial behavior

Assess the influence of hook geometry, epoxy properties, and timber density on bond performance

Experimental Setup

A typical pull-out test involves

Embedding a hooked GFRP bar in a timber block with an epoxy adhesive

Applying an axial tensile load to the bar while measuring displacement (slip) and load response

Monitoring failure modes (e.g., adhesive failure, timber crushing, or bar pull-out)

Analytical and Numerical Modeling

Empirical Models: Relate bond strength to material properties (e.g., timber density, epoxy shear strength)

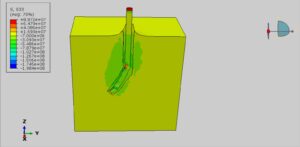

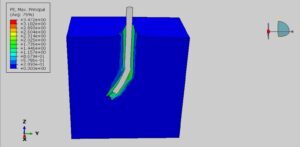

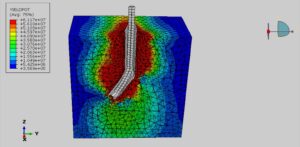

Finite Element Analysis (FEA): Simulates stress distribution and predicts failure modes

Bond-Slip Models: Describe the nonlinear relationship between shear stress and slip

Applications and Implications

Understanding the pull-out behavior of hooked GFRP bars in timber-epoxy systems helps in

Optimizing reinforcement design for timber connections

Developing design codes for FRP-reinforced timber structures

Improving adhesive selection and surface treatment techniques

Pull-out test analysis provides critical insights into the bond performance of hooked GFRP bars in timber-epoxy systems. Experimental, analytical, and numerical approaches help characterize bond strength, slip behavior, and failure mechanisms, ensuring safe and efficient structural applications

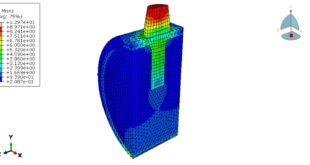

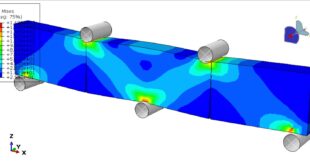

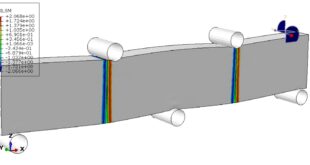

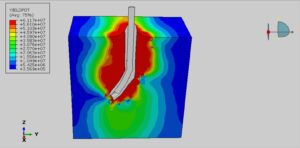

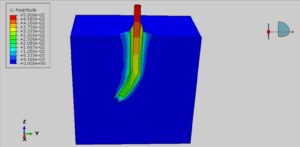

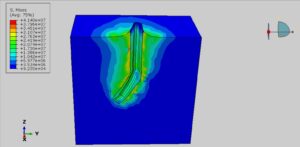

After the simulation, all results such as stress, strain, force-displacement diagram, deformation, and other are available. You can see some figures for the resutls below

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials