Welded steel structures are widely used in critical engineering applications such as offshore platforms, pressure vessels, pipelines, automotive frames, and defense structures. The structural integrity of these components is strongly influenced by the mechanical performance of welded joints, particularly under dynamic loading conditions such as impact, blast, and high-strain-rate tensile loading. Since welding introduces metallurgical heterogeneity and geometric discontinuities, the welded region often becomes the most vulnerable location for damage initiation and fracture

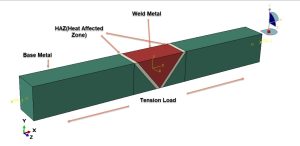

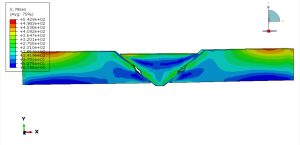

A typical welded joint consists of three distinct material zones: the Base Metal (BM), the Weld Metal (WM), and the Heat-Affected Zone (HAZ). Each zone exhibits different microstructural characteristics and mechanical properties due to the thermal cycles experienced during the welding process. The weld metal is formed from filler material, the heat-affected zone undergoes microstructural transformation without melting, and the base metal remains relatively unaffected. This material heterogeneity leads to non-uniform stress distribution and complex failure mechanisms when the joint is subjected to dynamic tensile loading

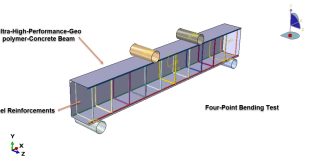

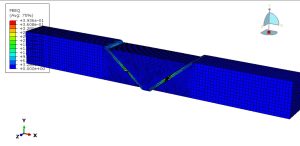

Dynamic tensile testing provides critical insight into strain-rate-dependent deformation, damage evolution, and fracture behavior of welded structures. However, experimental testing alone is often costly, time-consuming, and limited in its ability to capture localized field variables such as stress triaxiality, plastic strain localization, and damage progression. Therefore, advanced finite element (FE) simulation has become an essential tool for predicting the dynamic response and failure of welded joints. You can see the part is the assembly below

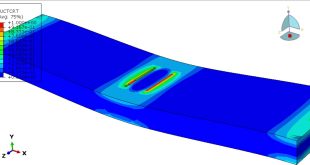

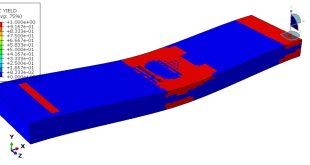

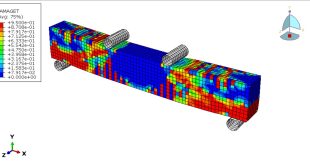

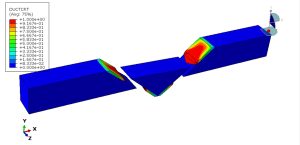

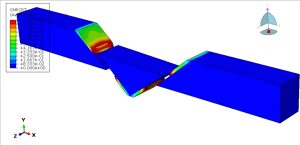

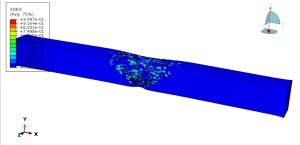

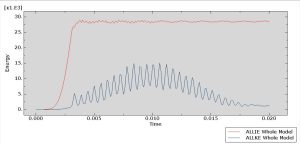

In this study, a three-zone finite element model of a steel plate with a welded mid-zone connection is developed using Abaqus/Explicit. The plate is partitioned into Base Metal, Heat-Affected Zone, and Weld Metal regions to accurately represent the material heterogeneity of the welded joint. All three materials are modeled using elastic-plastic constitutive behavior coupled with ductile and shear damage initiation and evolution criteria to simulate progressive degradation and fracture under high strain rates

The explicit dynamic solver is employed due to its robustness in handling highly nonlinear problems involving large deformation, high strain-rate loading, material failure, and element deletion. This approach enables accurate capture of crack initiation, propagation, and final separation within the welded region

The objective of this work is to investigate the stress–strain response, damage initiation sites, failure modes, and the influence of material mismatch among the three weld zones under dynamic tensile loading. The numerical results provide insight into the structural performance and fracture resistance of welded steel plates and contribute to safer and more reliable welded structural design

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials