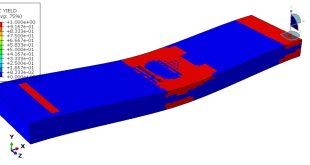

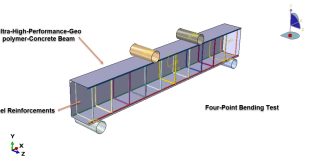

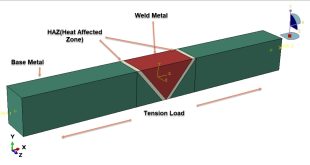

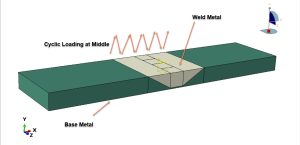

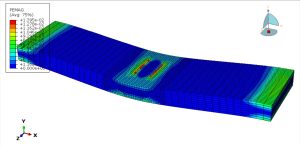

Welded steel structures are widely used in engineering applications such as bridges, offshore platforms, pressure vessels, and structural frames, where they are frequently subjected to repeated or cyclic loading rather than monotonic loads. Under such conditions, welded joints often become critical locations for damage initiation due to stress concentration, metallurgical heterogeneity, and residual stresses introduced during the welding process. Therefore, understanding the cyclic response of welded components is essential for predicting fatigue life, structural integrity, and failure mechanisms. You can see a figure of the part in assembly below

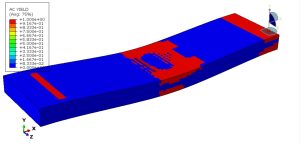

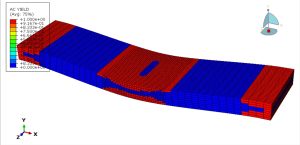

Both the base metal and the weld metal are modeled using an elastic–plastic constitutive framework. To accurately capture cyclic material behavior—particularly phenomena such as the Bauschinger effect, cyclic hardening/softening, and ratcheting—a combined isotropic–kinematic hardening plasticity model is employed. This model enables a realistic simulation of hysteresis loop evolution under repeated loading by accounting for

Isotropic hardening → expansion/contraction of the yield surface

Kinematic hardening → translation of the yield surface in stress space

Such combined plasticity formulations are well-suited for welded steel joints, where cyclic loading often produces nonlinear stress–strain responses

The loading is applied through a Static General analysis step in Abaqus. Although the loading is cyclic, the quasi-static assumption is appropriate because inertial effects are negligible, and the focus is on material nonlinearity rather than dynamic response. The cyclic load history is defined via time-dependent amplitude functions to generate repeated tension–compression (or load–unload) behavior

The finite element model is developed to capture

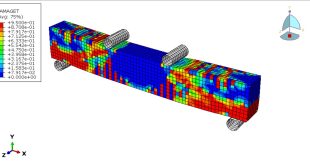

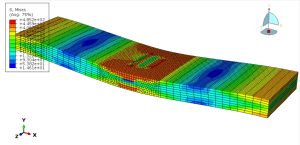

Stress and strain distribution across the weld and base metal

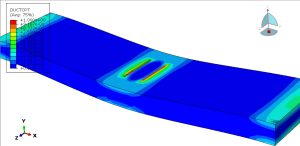

Localized plastic deformation near the weld interface

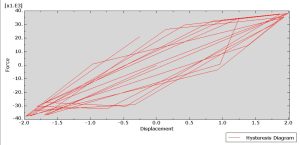

Evolution of hysteresis loops under cyclic loading

Potential sites for fatigue crack initiation

Special attention is given to the material mismatch between the weld metal and base metal, as this mismatch significantly influences strain localization and cyclic damage accumulation

The analysis yields hysteresis diagrams (stress–strain loops) extracted from critical regions, which are used to evaluate cyclic plasticity characteristics such as energy dissipation, cyclic stabilization, and hardening/softening trends

You can provide this simulation’s CAE, INP, and English video files here. The price of these files is Sixty Thirty Euros. You can click on the button below to begin the process

Our Payment methods are: Tether, Bitcoin, TRX, PayPal, Visa, or Mastercard. Just before payment, send us an email to this address: abaqusfem.com@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials