How can we design dental implants that work in harmony with the human jaw

Our latest research uses finite element modelling in Abaqus to explore the biomechanical behaviour of titanium foam implants—an innovative material designed to mimic the natural stiffness of bone

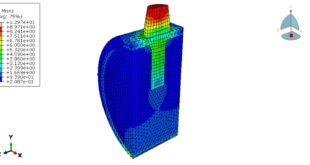

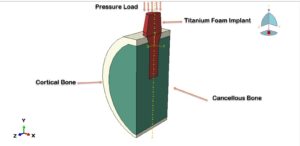

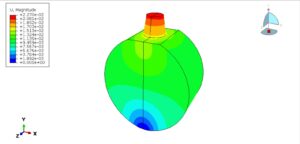

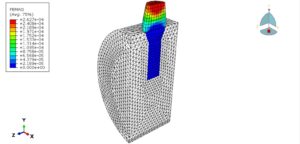

In this study, we simulate how a titanium foam implant interacts with surrounding bone under chewing forces. The implant is modelled as a crushable foam, capturing its unique ability to absorb load and reduce stress shielding. The jawbone is represented as two distinct layers: cortical bone and cancellous bone, both treated as linear elastic materials. You can see a figure of the titanium foam implant, cortical bone, and cancellous bone in the assembly below

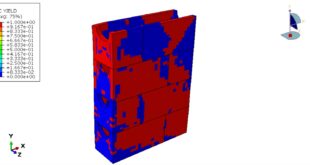

To model the implant, the Crushable foam material model is selected. When simulating advanced porous materials like titanium foams, the Crushable Foam material model is an essential tool for capturing their unique mechanical behaviour. This specialized constitutive model accurately represents how cellular structures deform and yield under load—something standard metal plasticity cannot address. Unlike dense metals that yield similarly in tension and compression, porous materials exhibit asymmetric yielding. They’re much weaker in compression, where pore walls buckle and collapse, than in tension. The Crushable Foam model captures this fundamental characteristic, making it indispensable for simulating

Metal foams (titanium, aluminum)

Polymeric foams

Biomedical implants

Protective packaging

Energy-absorbing structures

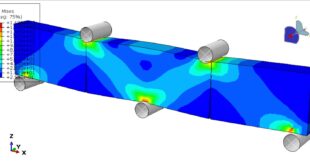

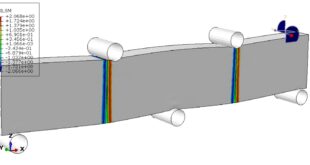

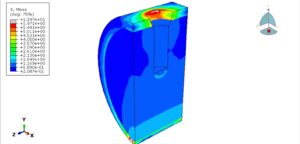

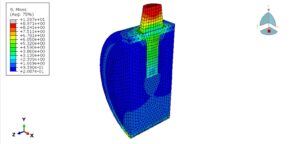

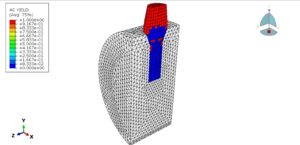

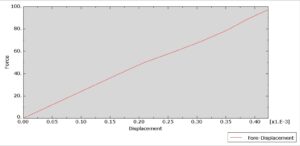

In this case, the three-dimensional modelling is considered to demonstrate all the aspects of modelling and simulation. The static step and perfect bond between the implant and bone are selected. To be sure about the results, the mesh around the contact zone should be fine. The load is applied to the top surface of the implant, and after the simulation, all results, such as stress distribution, displacement, force, and … are available. You can see some figures of the results below

You can provide this simulation’s CAE, INP, and English video files here. The price of these files is Thirty Euros. You can click on the button below to begin the process

Our Payment methods are: Tether, Bitcoin, TRX, PayPal, Visa, or Mastercard. Just before payment, send us an email to this address: abaqusfem.com@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials