Introduction

Lightweight sandwich composite structures have gained significant attention in aerospace, automotive, marine, and defense applications due to their high specific strength, excellent energy absorption capacity, and superior impact resistance. Among these, glass fiber–reinforced polymer (GFRP)–metal foam–GFRP composite panels represent a promising class of hybrid sandwich structures that combine the advantages of fiber-reinforced composites and cellular metals. When subjected to high-velocity impact (HVI), such as ballistic threats, debris strikes, or bird impacts, understanding their dynamic response and failure mechanisms is critical for safe and efficient structural design

GFRP face sheets offer high tensile strength, corrosion resistance, and cost-effectiveness, while aluminum foam cores provide low density, high compressive strength, and excellent energy absorption through progressive plastic deformation. The combination of GFRP skins and an aluminum foam core enables effective load distribution, delayed crack propagation, and enhanced impact energy dissipation compared to monolithic materials. However, the complex interaction between heterogeneous constituents, strain-rate sensitivity, and multiple damage modes under high-velocity impact presents substantial challenges for experimental investigation alone

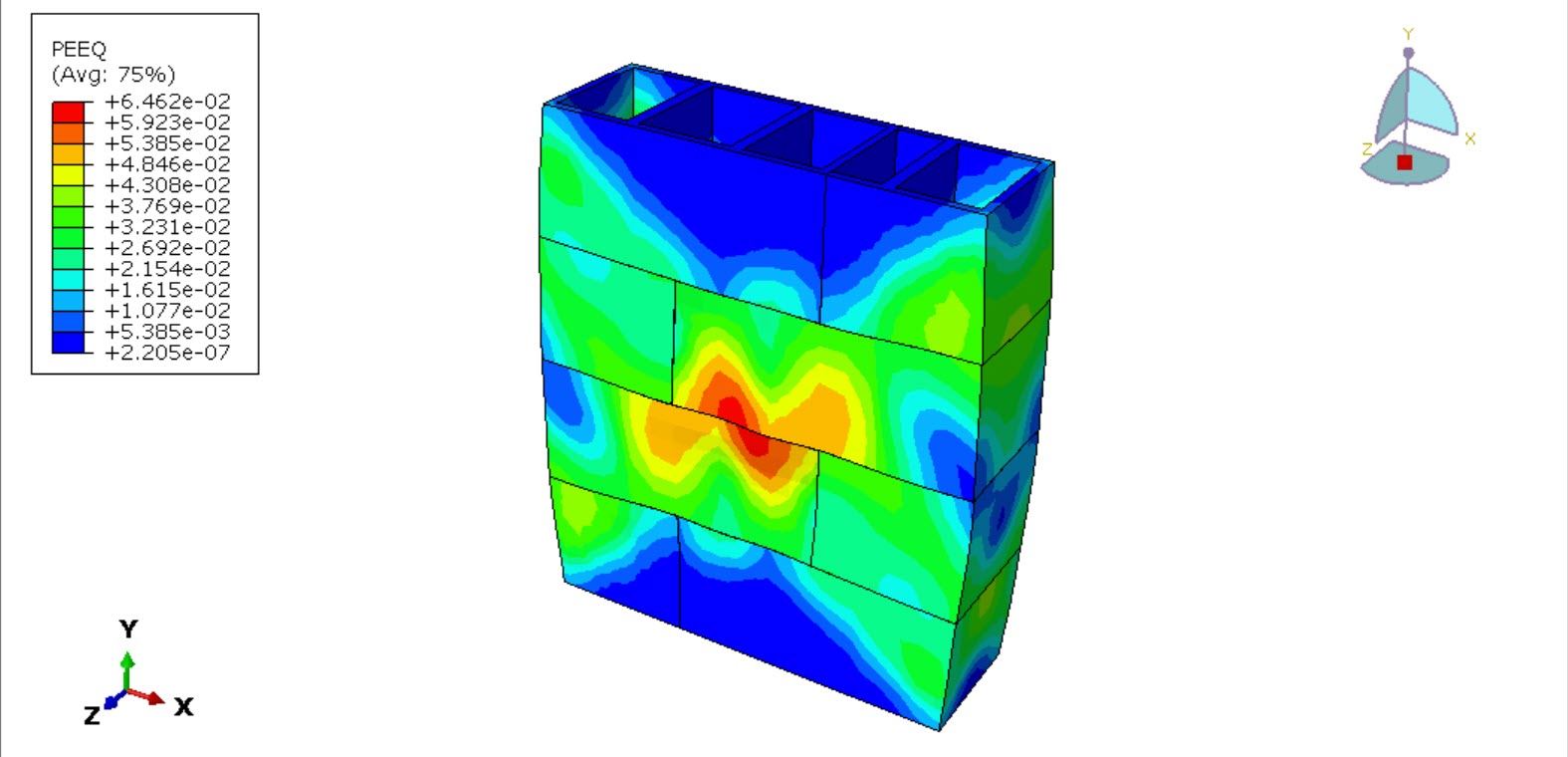

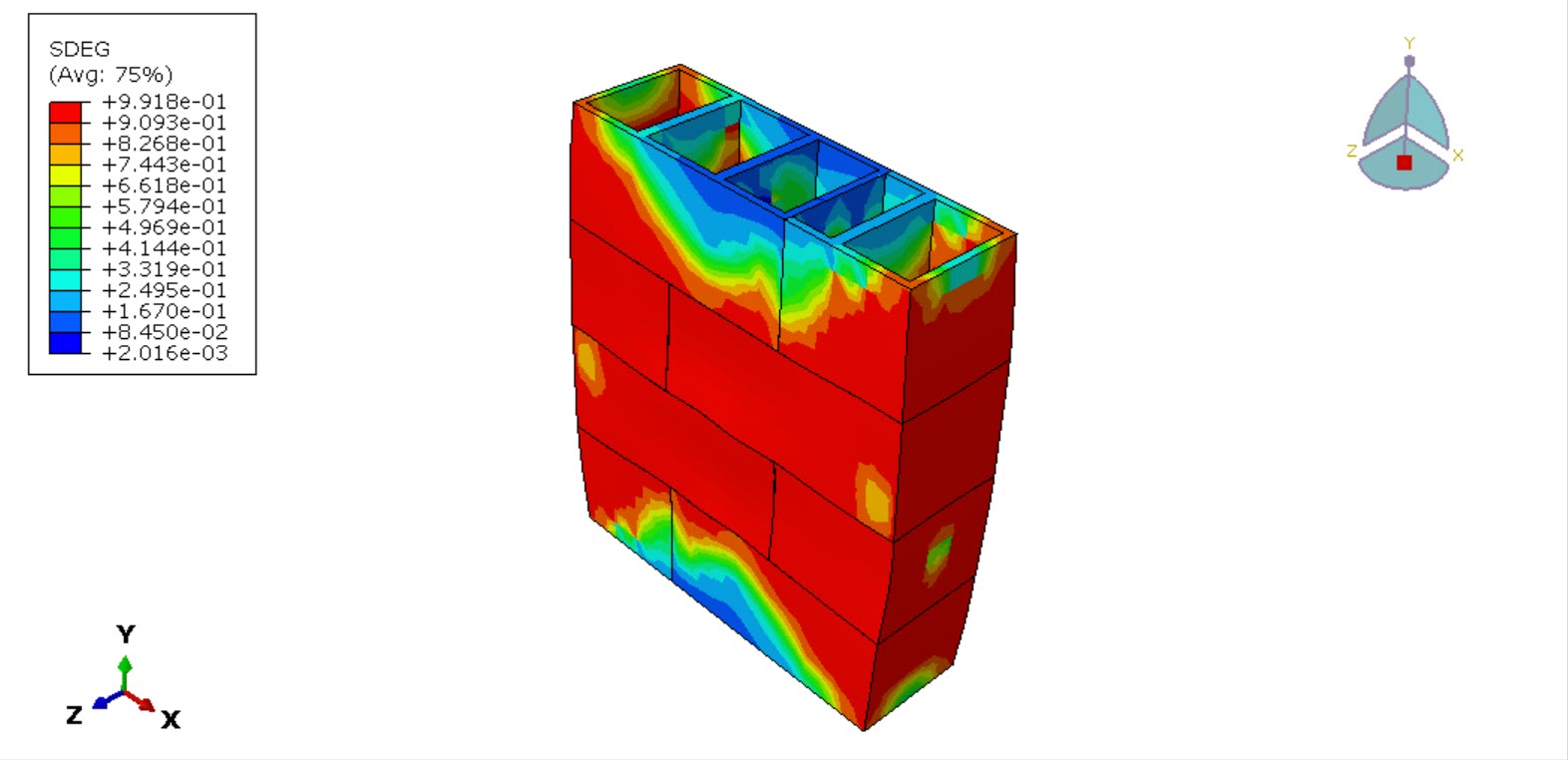

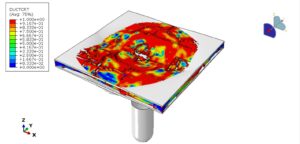

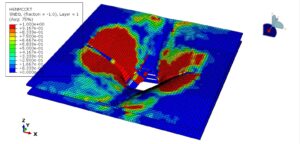

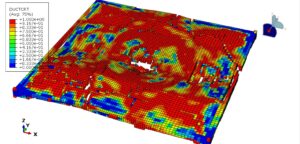

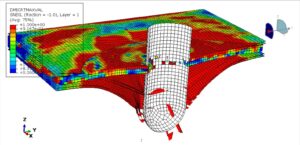

Numerical simulation, particularly using finite element (FE) and explicit dynamic methods, has therefore become an indispensable tool for analyzing the high-velocity impact behavior of GFRP–aluminum foam–GFRP composite panels. Simulation enables detailed insight into stress wave propagation, damage initiation and evolution, interfacial debonding, foam crushing, and projectile–target interaction at temporal and spatial resolutions that are difficult to achieve experimentally. Constitutive models that account for strain-rate effects, progressive damage in composites, and plastic collapse in metal foams are essential for accurately predicting impact responses, including penetration depth, residual velocity, energy absorption, and failure patterns.

The present study focuses on simulating a GFRP–aluminum foam–GFRP sandwich panel subjected to high-velocity impact, aiming to capture the dynamic response and dominant failure mechanisms of the composite system. By employing appropriate material models and contact algorithms, the numerical framework provides a cost-effective and reliable approach for parametric studies and design optimization. The outcomes of such simulations contribute to improved understanding of impact resistance in hybrid sandwich structures and support the development of lightweight, high-performance protective systems

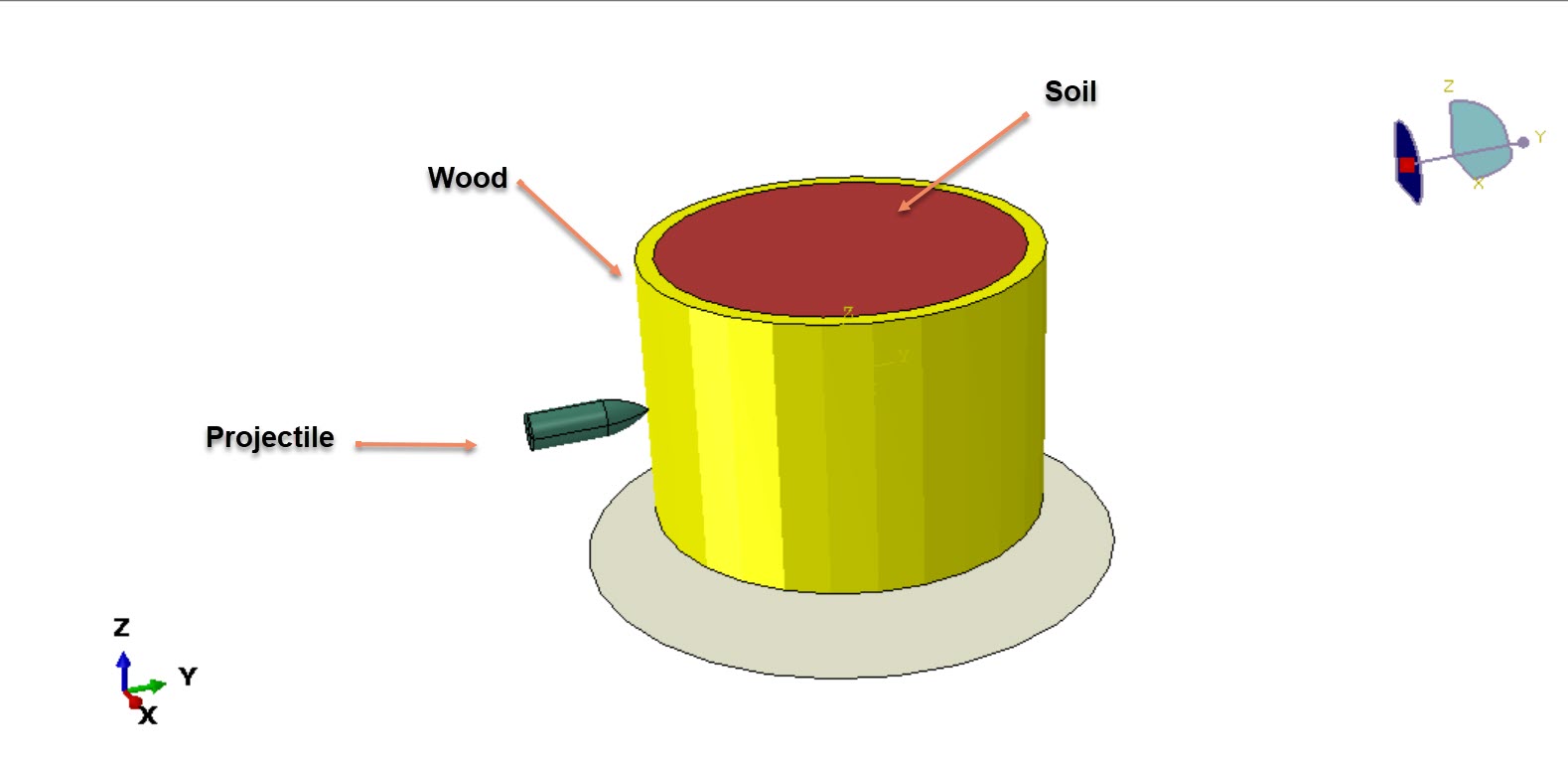

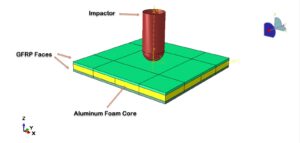

In this example, the aluminum foam core is modeled as a three-dimensional solid using an elastic–crushable foam hardening model in conjunction with a ductile damage criterion. The two GFRP face sheets are modeled as three-dimensional shell elements with multiple laminate layers. The Hashin damage failure criterion is employed to capture the progressive failure of the GFRP laminates under impact loading. A dynamic explicit analysis step, along with appropriate interactions, loading conditions, and mesh definitions, is adopted

During this course, you will learn the fundamentals of high-velocity impact analysis of composite sandwich panels with GFRP face sheets and an aluminum foam core. The example covers all essential aspects of the analysis, including geometry definition; material models such as crushable foam with ductile damage and the Hashin damage criterion; dynamic explicit step setup; interactions; loading and boundary conditions; mesh generation; and, finally, interpretation of the simulation results

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials