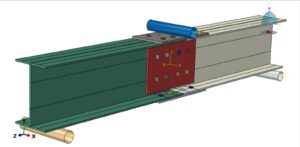

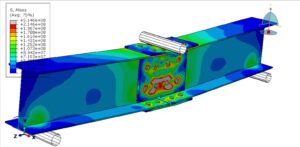

The dynamic analysis of three-point bending tests on bolted steel splice connections provides vital insight into the structural performance of steel members subjected to impact or rapidly applied loads. Unlike quasi-static loading, dynamic bending introduces strain-rate effects, inertia forces, and potential changes in failure mechanisms that can significantly influence the connection’s stiffness, ductility, and energy dissipation capacity. In steel structures, bolted splice connections are widely used to join beam segments, transfer forces, and maintain structural continuity, making their behavior under dynamic bending actions critical for assessing overall structural reliability—particularly in applications such as bridges, industrial buildings, cranes, and structures exposed to seismic or accidental loading scenarios

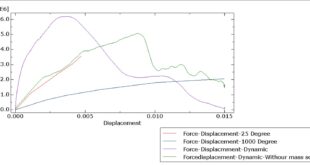

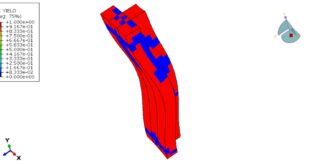

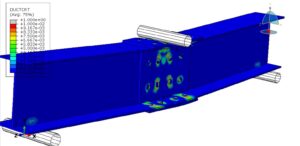

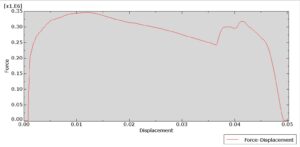

Three-point bending tests allow a controlled means of evaluating the bending strength and deformation response of a splice connection while isolating parameters such as bolt preload, bolt arrangement, friction, plate thickness, and material grade. Under dynamic loading, factors such as bolt slippage, local plate deformation, frictional energy dissipation, and potential bearing failure at the bolt holes become more prominent. Experimental testing, complemented by numerical modeling, can be used to characterize these behaviors, allowing researchers to quantify dynamic amplification, identify changes in failure mode, and improve analytical or design models for real-world applications

Overall, understanding the dynamic response of bolted steel splice connections under three-point bending is essential for designing safer, more reliable steel structures capable of withstanding rapid or unforeseen loading conditions

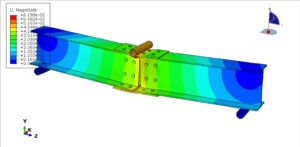

The beams and bolts are modeled as three-dimensional solid parts. Elastic-plastic behavior is used for all members to consider the plastic deformation of beams and bolts. Both static and dynamic approaches can be used in this example, but the dynamic form with mass scale techniques can help much to overcome the non-convergence issue.

The course includes a detailed tutorial video that explains every step, including geometry creation, material data input, assembly, step definition, interactions, loading, meshing, and result interpretation

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials