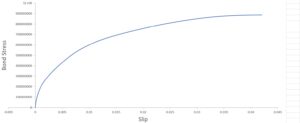

Bond–slip behavior is a fundamental aspect of reinforced concrete mechanics, governing how stresses are transferred between reinforcing bars and the surrounding concrete. For ribbed steel reinforcement, this interaction is dominated by mechanical interlock, surface friction, and the progressive formation of microcracks within the concrete matrix. Understanding this behavior is essential for accurately predicting the structural performance of concrete members, as bond directly influences load transfer, crack control, stiffness, and overall structural reliability.

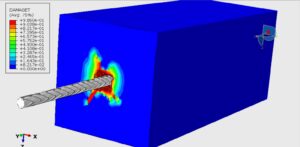

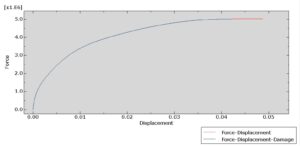

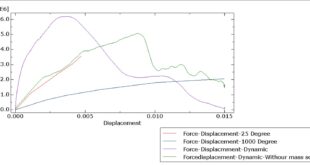

The pull-out test is one of the most widely used methods for evaluating local bond mechanisms under controlled conditions. By embedding a ribbed steel bar in a concrete specimen and applying axial force to the bar, the test provides detailed insight into the relationship between applied load, interfacial stress, and resulting slip. However, because the bond response is inherently nonlinear—affected by concrete crushing, rib geometry, confinement, and damage evolution—experimental data alone may not fully capture the underlying mechanics.

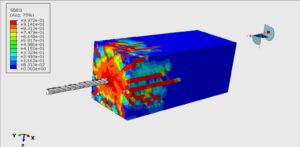

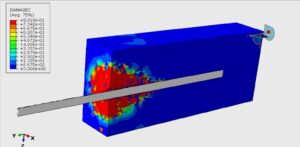

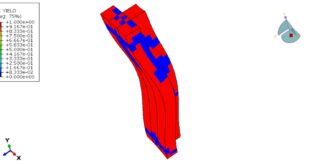

Numerical pull-out simulations offer a powerful complementary approach, enabling researchers to examine stress distributions, crack patterns, and slip evolution with a level of detail difficult to obtain experimentally. Through the use of appropriate constitutive models for concrete and steel, as well as realistic interface laws to represent the mechanical interlock of the ribs, simulations can reproduce key features of the bond–slip curve and provide deeper insight into failure modes.

Studying the bond–slip behavior in the pull-out simulation of ribbed reinforcement from concrete, therefore, provides a valuable understanding of the complex interaction at the steel–concrete interface, supporting improved design of reinforced concrete structures and more accurate predictive models of their performance

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials