Key mechanisms observed experimentally and in simulations include:

-

Ceramic fracture and comminution. On impact, the ceramic locally shatters, producing a conical crushing zone and ejecta that blunts and fragments the projectile. The degree of ceramic fragmentation controls how much kinetic energy is transferred to the backing

- Stress-wave transmission and bulging. Stress waves generated in the ceramic propagate into the backing, causing radial bulging and distributed loading — spreading the load over a larger area reduces local penetration. Studies quantify bulge propagation and back-face deformation as primary dr

- UHMWPE dissipation mechanisms. The polymer backing dissipates energy by tensile fiber stretching, delamination, fiber breakage/pullout, and large plastic deformation of the matrix or binder. Backing stiffness and adhesive properties influence the lateral motion of tiles and the multi-hit performance of stopping performance

Because ballistic impact involves high strain rates, large pressures, and brittle failure, the following models are most commonly used in the literature:

-

Johnson–Holmquist (JH-2) for ceramics: captures pressure-dependent strength, damage evolution, and post-fracture residual strength; widely used for Al₂O₃, SiC modelling in ballistic studies and code implementations (LS-DYNA, Abaqus with user subroutines, etc.). Parameterization remains nontrivial and often requires dedicated tests (Hugoniot, quasi-static strength, dynamic compressive tests)

- Hashin-type 3D failure criteria for fiber-reinforced composites and UHMWPE laminates: used to predict fiber/matrix tension, compression, and shear-driven damage modes; extended forms (Matzenmiller, Puck, progressive damage models) are used to capture delamination and progressive softening

- Johnson–Cook for ductile metallic components (projectile core, metallic backers) — used for target/penetrator interaction, large strain, and strain-rate effects. J–C is often paired with erosion/element deletion to allow perforation

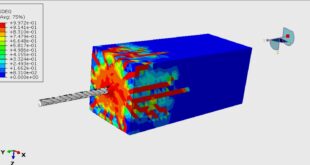

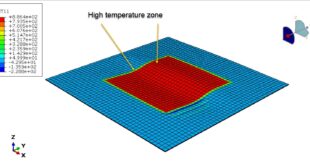

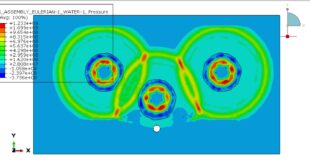

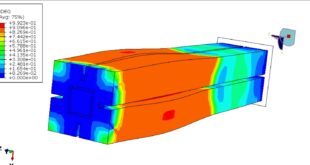

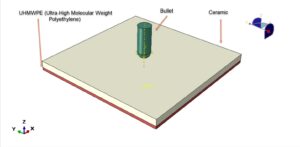

During this course, you will learn all the details involved in analyzing the penetration resistance of ceramic–UHMWPE armor against ballistic bullet impact using Abaqus software through a comprehensive tutorial. The topics covered include geometry definition, material models such as JH-2, Hashin, and Johnson–Cook, explicit step setup, erosion modeling using general contact capabilities to account for internal element failure, meshing, and results analysis.

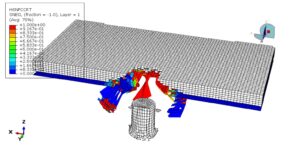

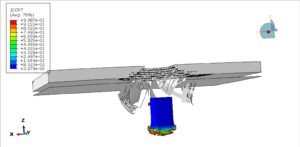

After the simulation, all results, such as stress, strain, damage, failure, bullet depth penetration, and diagrams, are available. You can see some figures of the results below

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials