A wood-steel plate connection with bolts is a common structural joint used in timber construction to transfer loads between wooden members and steel plates. This type of connection is widely used in beams, columns, trusses, and hybrid structures due to its strength, durability, and ease of assembly

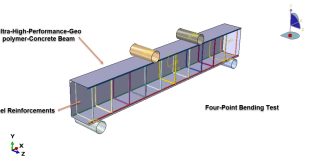

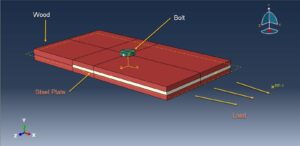

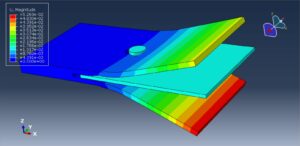

You can see a figure of the assembled parts of wood, steel plate, and bolt

Key Components of the Connection

Wood Member – Typically a glulam, LVL, or solid timber element

Steel Plate – Acts as a connector, often made of mild steel (e.g., A36) or high-strength steel

Bolts – Usually hex bolts, carriage bolts, or fully threaded rods (ASTM A307 or higher grade)

Washers & Nuts – Distribute clamping force and prevent bolt pull-through

Optional Adhesives/Sealants – Used to improve stiffness and moisture resistance

Failure Modes to Check

Wood Splitting (due to insufficient edge distance)

Bolt Shear Failure (if bolts are undersized)

Bearing Failure in Wood (crushing around bolt holes)

Steel Plate Yielding/Buckling (if too thin)

Bolt Withdrawal (if tension forces are present)

Construction Steps

Fabricate a steel plate with pre-drilled holes

Mark & pre-drill wood (avoid splitting)

Assemble with bolts, washers, and nuts

Tighten evenly to avoid uneven clamping

Check for gaps and ensure full contact

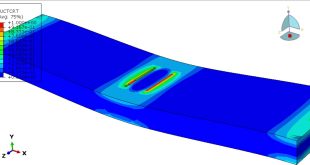

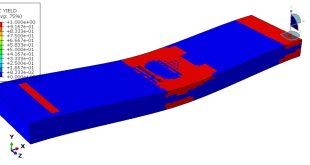

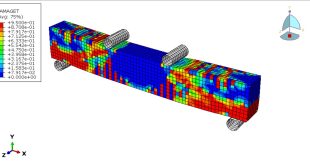

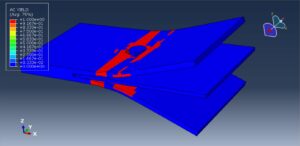

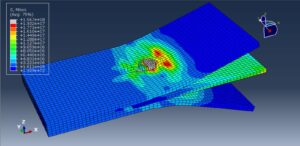

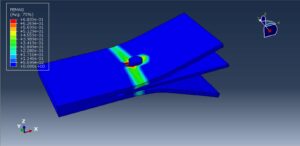

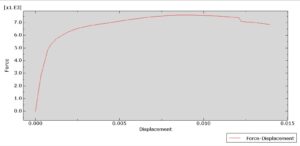

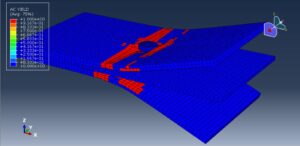

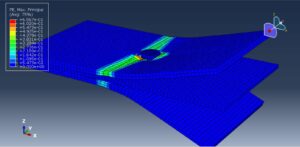

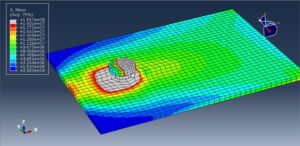

The important thing in the simulation is the material model of the wood, it can be an elastic-plastic model with damage behavior. After the simulation, all results such as stress, strain, damage, failed zones, force-displacement, and other results are available. You can see some figures of the results below

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials