In this tutorial simulation profiled steel deck composite slab system under four point bending in Abaqus has been studied. Composite slabs comprised of cold-formed profiled steel sheet and structural concrete topping are commonly used nowadays for the construction of buildings. In this system, steel deck serves as a permanent form work for supporting the concrete and also acts as tensile reinforcement.The strength and performance of the composite slab is also influenced by other factors such as profile geometry, thickness of steel sheeting, concrete types/compressive strength, span, embossments/shear connectors and steel-concrete interface shear bond con-trolling the composite action.By adopting suitable profile geometry with or without embossments sufficient resistance against steel-concrete vertical separation and horizontal slippage can be achieved. The interfacial shear depends on several parameters, including the height, shape, and orientation of the embossment pattern and other shear connectors

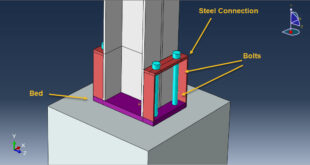

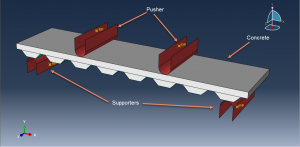

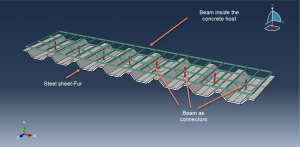

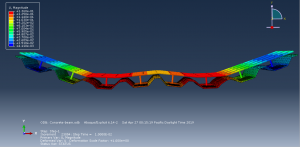

The concrete is modeled as three dimensional part,steel deck as shell part,bars as wire and the connectors between concrete and deck are modeled as beam element.You can see some figures of the assembled parts at below

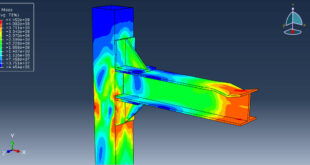

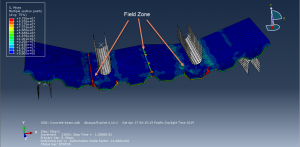

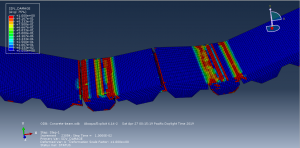

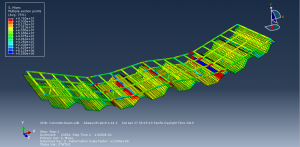

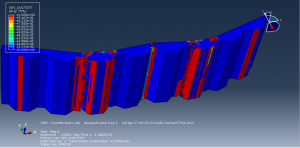

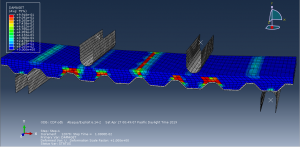

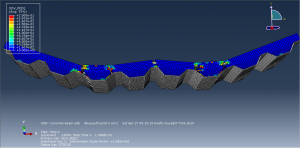

For concrete two material model (Johnson Holmquist and CDP) has been used to observe damage propagation under bending. The steel material is defined as elastic plastic material with ductile damage data. Dynamic explicit step with smooth amplitude to apply the smooth load has been selected. Surface to surface contact among rigid bodies and deformable pars has been selected. The bar and connectors are used as embedded parts in the concrete host. The contact between deck and concrete is assumed as ideal contact.The boundary conditions are assigned to all rigid bodies. After the simulation the damage and stress ….result can be achievable .

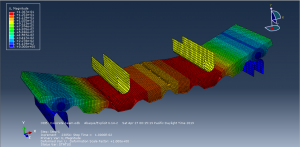

You can see some figures of the results at below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Eight Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس