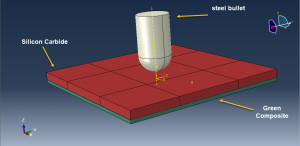

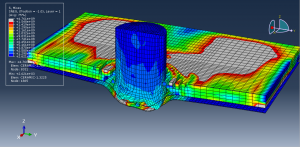

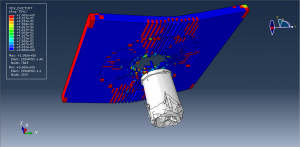

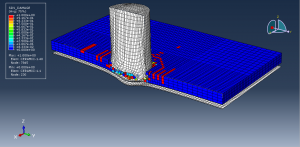

In this tutorial the Simulation ballistic impact of steel bullet to the ceramic panel reinfroced with Green Composite has been investigated. The bullet is modeled as a three-dimensional solid part, the ceramic panel as a solid part, and the green composite as a three-dimensional shell part. You can see a figure of the assembled part below

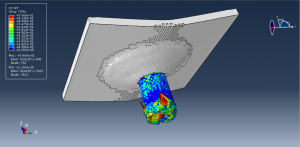

To model steel bullet material with rapid deformation, Johnson-Cook plasticty and damage is selected. The Johnson-Cook plasticity model is a particular type of Mises plasticity model with analytical forms of the hardening law and rate dependence, and suitable for high-strain-rate deformation of many materials, including most metals. Abaqus/Explicit provides a dynamic failure model specifically for the Johnson-Cook plasticity model, which is suitable only for high-strain-rate deformation of metals

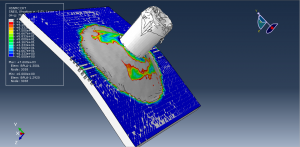

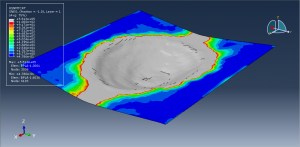

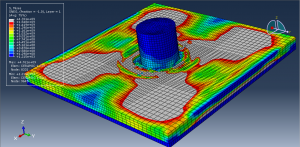

To model Ceramic behavior Johnson-Holmquist consitive model is considered, the JH-2 model assumes that the damage variable increases progressively with plastic deformation. To model green composite with several layup, Hashin’s damage criterion is used. Damage initiation refers to the onset of degradation at a material point. In Abaqus the damage initiation criteria for fiber-reinforced composites are based on Hashin’s theory. These criteria consider four different damage initiation mechanisms: fiber tension, fiber compression, matrix tension, and matrix compression

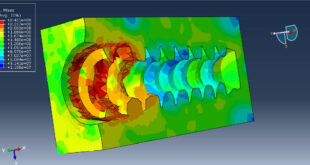

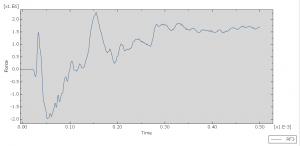

Dynamic explicit step with specific time durition is appropraite for this type of analysis. The general conctact algorithm with contact property amoung all parts is selected. To define the contact between ceramic panel and green composite plate, the Tie constraint is used. The fix boundary condition for ceramic panel and initial velocity for the bullet in the load section are applied. The mesh should be fine to get proper results. After the analysis, all results such as stress, strain, damagae, crater, depth of penetration, force, … are avaiable. You can see some figures below for the results

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس