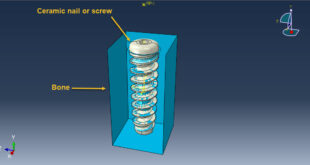

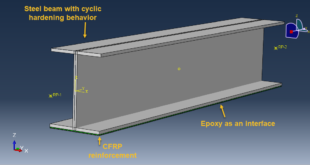

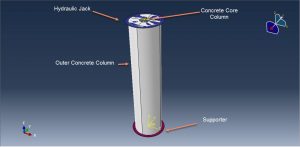

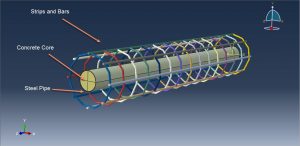

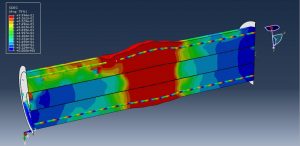

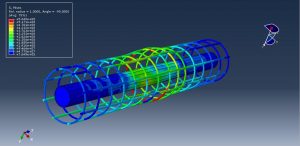

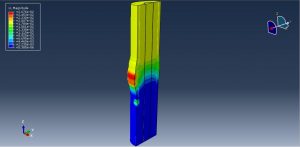

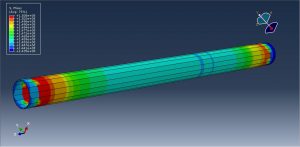

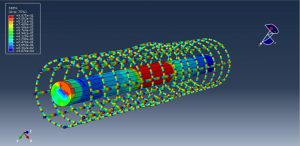

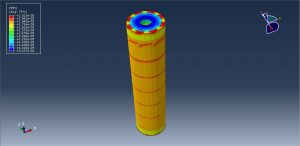

In this tutorial, the Simulation circular concrete-encased concrete-filled steel tube (CFST) stub columns subjected to axial compression in Abaqus has been investigated. Compared with CFST columns, the advantages of concrete-encased CFST columns include higher stiffness, convenient connection with RC beams, and higher resistance to fire and corrosion. In addition, a thinner steel tube can be applied in the column due to the support from both the outer and core concrete. When compared with RC columns, the concrete-encased CFST columns provide higher strength and better ductility, and allow for the use of high-strength concrete as core concrete in the inner CFST, resulting in a smaller cross-section. During construction, the inner CFST is constructed first and then acts as a support to carry the construction load before the assemblage of the outer RC component. After the installation of the external formwork and reinforcement, the outer concrete is finally placed. The concrete-encased CFST has different configurations resulting from the combinations of various sections, that is, square or circular inner CFST and square or circular outer RC. The concrete core, steel pipe, and outer concrete parts are modeled as three-dimensional solid parts. The strips and bars are modeled as wire parts. You can see figures of the assembled parts below

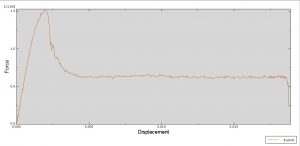

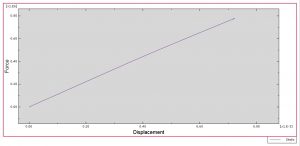

The elastic-plastic steel material is used for the strips and bars. The steel material for the pipe is implied with elastic-plastic material and ductile damage criterion to predict damage during the analysis. The Concrete Damaged Plasticity for concrete parts are used. The model is a continuum, plasticity-based, damage model for concrete. It assumes that the main two failure mechanisms are tensile cracking and compressive crushing of the concrete material. The two analysis is used in this simulation. In the first case, general static step is selected to consider static compression. In this case, the time of the simulation is too long, but the results are so reliable. To decrease the simulation time, in the second case, the dynamic simulation is used. This procedure can reduce simulation time. The general contact algorithm with contact property is applied to all contact domain. The perfect contact is assumed between the concrete core and the inner surface of the steel pipe and the outer surface of the steel pipe and the outer concrete part. The fixed boundary condition is considered for the bottom rigid body and displacement with amplitude for the top rigid body. The mesh should be fine to have a better convergence

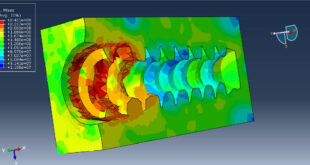

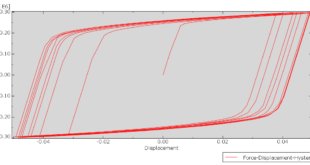

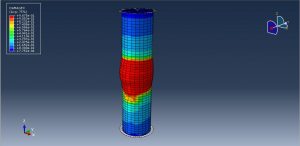

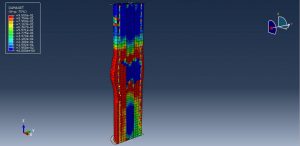

After the simulation, all results such as stress, strain, tensile and compression damage, force-displacement diagram, and ….are obtainable. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس