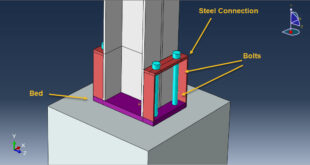

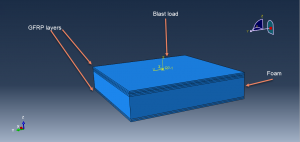

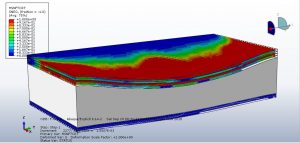

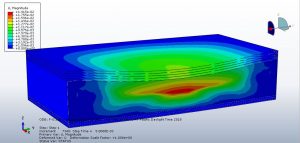

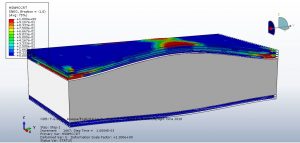

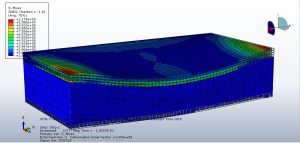

In this simulation the air-blast response of sandwich panels with composite face sheets (GFRP) and foam cores has been investigated.Sandwich panels based on two relatively stiff face sheets separated by a foam core are commonplace in the marine industry.for example in surfboard and yacht construction. Lightweight sandwich materials are attractive options for the transport industry which is seeking to improve fuel economy and speed whilst reducing harmful emissions. At the same time, there is a competing requirement for vehicles to be protected from explosions which traditionally involves the use of strong, relatively ductile metals such as armour steel. The position of GFRP layouts and foam has shown in below figure

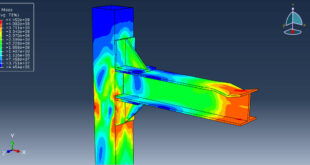

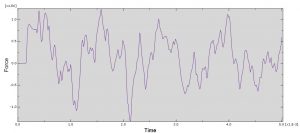

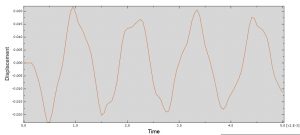

To model GFRP , Hashin’s damage criterion and for foam Crushable material model have been used. Dynamic explicit procedure is appropriate for this type of analysis. For modeling detonation behavior of TNT ,CONWEP procedure is selected and during the analysis blast wave create damage over facial composite layouts but after that the foam core absorb the detonation energy and the back plate composites stayed intact. The foam has large deformation because of absorbing energy and you can see some figures of this simulation at below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Four Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس