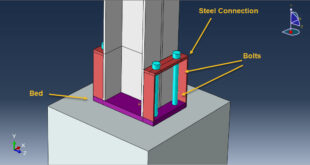

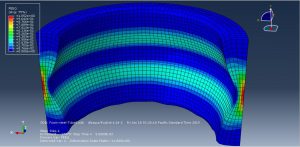

Foams, a new class of ultra-light materials, can absorb a large amount of kinetic energy because of their ability to undergo large deformation at a nearly constant plateau stress. Foam-cored sandwich structures have received increasing attention because of their excellent property of withstanding blast loading, and have been extensively used in marine and other military applications. The remarkable performances of sandwich structures depend on the innovative geometrical design of the foam core.Furthermore, traditional blast-resistant devices perform with low efficiency and heavy weigh. Lightweight and improved blast-resistant containment vessels have become popular with the increase in terrorism. The sandwich tube has been considered a novel structural design that can enhance blast-resistant vessels to contain explosive materials, and protect persons or equipment from internal explosion . The foam-cored sandwich tube has better energy absorption (EA) capability than the monolithic blast-resistant tube because the sandwich structures can undergo extreme plastic deformation at an almost constant plateau stress.The dynamic response of sandwich tubes received increasing attention over the last decade.You can see a figure of the real piece at below

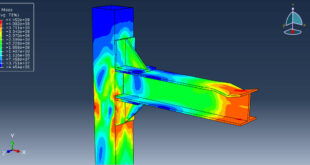

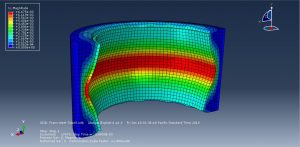

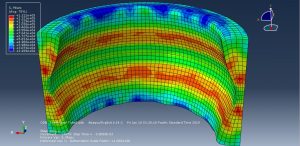

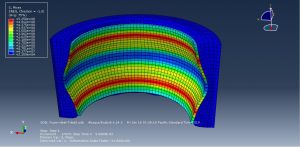

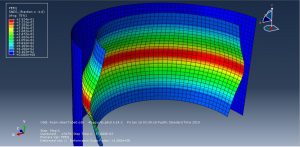

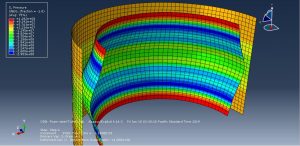

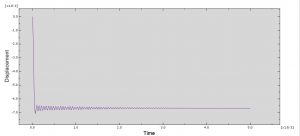

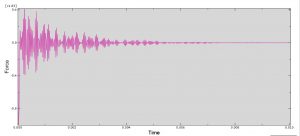

Johnson-Cook plasticity for tubes and crushable foam with hardening for foam has been used to evaluate the compaction of foam and deformation of tubes. Dynamic explicit step is appropriate for this type of analysis. The contact between steel tubes and foam is considered as perfect contact and CONWEP air blast procedure has been selected to imply blast load over the internal surfaces.During the analysis the blast causes a large deformation on the internal pipe and this deformation causes a huge compaction on the foam part. You can see some figures of the result from this simulation at below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Three Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس