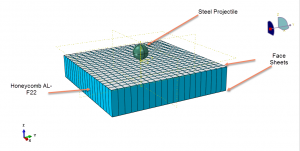

Sandwich panels are widely used in lightweight construction especially in aerospace industries because of their high specific strengths and stiffnesses. In the service life of a sandwich panel, impacts are expected to arise from a variety of causes. Debris may be propelled at high velocities from the runway during aircraft takeoffs and landings. Other examples include tools dropping on the structure during maintenance or even collisions by birds. Visual inspection may reveal little damage on the sandwich panel, but significant damage may occur between the impacted facesheet and the core. Reduction of structural stiffness and strength can occur, and consequently, propagate under further loading. Thus, their behaviour under impact has received increasing attention. Finite element modelling is one popular and cost-effective approach involved in the study of sandwich structures. To attain efficiency in numerical analysis, the core in sandwich structures, which has a large number of cells, is usually replaced with an equivalent continuum model. The sandwich panels are analysed in terms of their effective properties rather than by consideration of their real cellular structure. A number of experimental and analytical techniques have been proposed to predict the effective continuum properties of the core in terms of its geometric and material characteristics. modified the classical laminate theory and applied it on a unit cell to derive the equivalent elastic rigidities for the honeycomb core. How ever, theoretical formulation of the effective elastic constants for the core could be tedious or almost impossible if the sandwich construction is too complicated. Even if it is possible, the mathematical derivations for one type of sandwich core might not be applicable to other types.You can see a figure of assemble parts at below

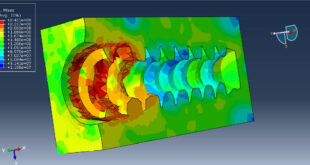

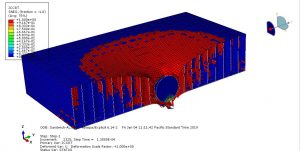

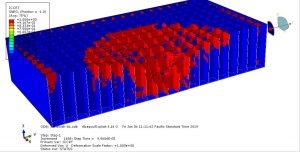

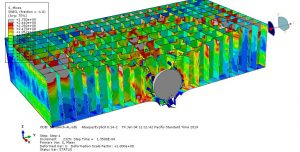

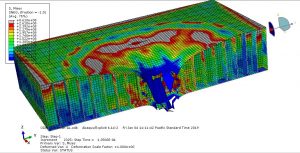

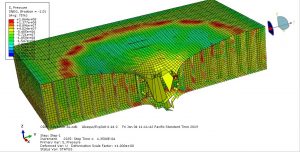

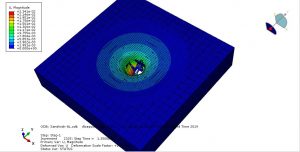

In this simulation projectile is modeled as three dimensional part with steel material and the honeycomb with two facial sheet are modeled as three dimensional shell with Aluminium material. Johnson-Cook plasticity and damage has been used for both bodies. Dynamic explicit procedure is appropriate for this type of analysis . the contact between honeycomb and facial sheet is considered as perfect contact and between projectile and upper surface , surface to surface with contact property has been implied.Because of the projectile high initial velocity the deformation and damage on the sandwich panel is be clear and the JC damage parameter is available after the impact. You can see some figures of the results at below.

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Three Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس

آموزش آباکوس از مقدماتی تا پیشرفته/شبیه سازی در آباکوس/فیلم های آموزشی آباکوس آموزش آباکوس/ مقدماتی تا پیشرفته/شبیه سازی پدیده های مختلف در آباکوس/دانلود ویدئوهای آموزشی آباکوس